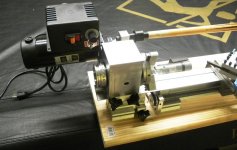

Sneek peak of my new autofeed copier combo, will fit on any hightower or todd's cue lathe.

Call for more details 248-884-4469

price is not set yet, it will be under $1200 for everything, including router router bracket and carraige attachment for tapering and duplicating.

TO BUY THE LATHE WITH EVERYTHING $2600 WITH FREE SHIPPING.( INCLUDES ROUTER AND BRACKET)

Auto feed has built in speed control and is its reversable too, you will be able to set up the stop ( off/Rev) switch any where along the 44" travel.

How this kit works:

The kit comes with 3 dove tail pieces predrilled to replace the 3 board mounted bracket to u-channel, once you replace those brackets with the dove tail pieces, then you can just slid the bed over the dovetail coupler blocks ( already mounted to board) Clamp down the blocks to hold the bed down.

now you got dovetail on the top and bottom, the bottom dovetail is also used to reposition the copier ( short or long pieces)

The copier has 2 true self centering heads, below that, you will see a slot, that is were the regular taper bar( similar to hightowers ) will mount. so if you want to make your own taper you still can, and if you just want to copy a certain taper, you can too.

PS: I will post a video showing how this whole machine works early next week. I will cut down a dowel and copy a shaft taper, I will also post a video showing the run out of my headstock front and back chuck, garenteed to be better that 0.0035" or you can return it for a new one.

I also added the indexer now which threads on instead of the rear chuck, the indexer is also a pulley for optional rear belt drive, the same motor can be re-mounted 180deg off its horizontal axis for rear belt drive, which is standard for my 1/3HP motor and my portable toolbox lathe.

Starting September 1, all my Cue Lathe line up will have a 1.4" Bore headstock standard, with the best prices and best quality around.

Best Regards

Call for more details 248-884-4469

price is not set yet, it will be under $1200 for everything, including router router bracket and carraige attachment for tapering and duplicating.

TO BUY THE LATHE WITH EVERYTHING $2600 WITH FREE SHIPPING.( INCLUDES ROUTER AND BRACKET)

Auto feed has built in speed control and is its reversable too, you will be able to set up the stop ( off/Rev) switch any where along the 44" travel.

How this kit works:

The kit comes with 3 dove tail pieces predrilled to replace the 3 board mounted bracket to u-channel, once you replace those brackets with the dove tail pieces, then you can just slid the bed over the dovetail coupler blocks ( already mounted to board) Clamp down the blocks to hold the bed down.

now you got dovetail on the top and bottom, the bottom dovetail is also used to reposition the copier ( short or long pieces)

The copier has 2 true self centering heads, below that, you will see a slot, that is were the regular taper bar( similar to hightowers ) will mount. so if you want to make your own taper you still can, and if you just want to copy a certain taper, you can too.

PS: I will post a video showing how this whole machine works early next week. I will cut down a dowel and copy a shaft taper, I will also post a video showing the run out of my headstock front and back chuck, garenteed to be better that 0.0035" or you can return it for a new one.

I also added the indexer now which threads on instead of the rear chuck, the indexer is also a pulley for optional rear belt drive, the same motor can be re-mounted 180deg off its horizontal axis for rear belt drive, which is standard for my 1/3HP motor and my portable toolbox lathe.

Starting September 1, all my Cue Lathe line up will have a 1.4" Bore headstock standard, with the best prices and best quality around.

Best Regards

Attachments

Last edited: