Not a very lot but I trust that I will do well, I'm a good machinist and I have a lot of knowledge in many domain. My intention is to do one table first, we have 24 tables here. I want to put 11 support by end slate, all mounted with bolt that I will be able to push and pull, 9 all aroud the slate that the bolt will pass through the slate and two that I will glue the block support to the slate, one at seam and one right in the middle of the slate. The support will be bolted on the frame and and the bolt that pass through the slate will pass through the support with a flat washer and a nut on each side, I know that make a lot of support point but I want to married the slate to the frame. Made a little draw of the support, that take me 1 minute and half...

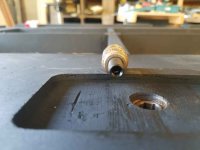

The table photo:

View attachment 711349

zupimages.net