I would think a 5” circular hand held Dewalt palm sander with 220 sandpaper would do the job just fine without taking off any measurable amount of slate.I have a blue diamond table that I’m looking to get leveled and recovered but wanted to know the best way to get any glue residue and gluey felt residue off the sores to present for a smooth clean setup?

Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best way to clean the slate?

- Thread starter Dropabomb

- Start date

Its pretty clear you have not actually done this. The amount of spray glue is ridiculous. That paper would keep gumming up, fact.I would think a 5” circular hand held Dewalt palm sander with 220 sandpaper would do the job just fine without taking off any measurable amount of slate.

TFT

Would MEK melt the glue?Its pretty clear you have not actually done this. The amount of spray glue is ridiculous. That paper would keep gumming up, fact.

TFT

I know how dangerous and nasty it is. Just curious if you tried other chemicals than the acetone mentioned..

I agree with not sanding it due to gumming up the paper...

Acetone is for the WAX and over time might break down the spry glue. Toulene was mentioned earlier work on the Adhesive. I used to use Klean Strip Adhesive remover, they took out the methylene Chloride and now it barely works. It used to MELT the adhesive in minutes..... MEK probably would work, but who carries such stuff for a table set up?? I do feel for the guy, he is a nice guy and I was clear with him on the issues. I been doing this way to long to be messing with all that stuff. I take my time and was already planning on being there 6-8 hours minimum because I had to cover the rails onsite. Add the extra ????? who knows how long to clean up those slates.. Not to mention I could tell they were gonna be a nightmare by how the last guy had all of the levelers so maxxed out. He had originally called for a Brunswick and I did not have a 4, he went his own way and I was trying to help out. Not going through all of that kind of stuff EVER again. I know how to make money and that aint it.Would MEK melt the glue?

I know how dangerous and nasty it is. Just curious if you tried other chemicals than the acetone mentioned..

I agree with not sanding it due to gumming up the paper...

TFT

Nope. Tried it. The glue is too rubbery. You're changing sandpaper every 30 seconds.I would think a 5” circular hand held Dewalt palm sander with 220 sandpaper would do the job just fine without taking off any measurable amount of slate.

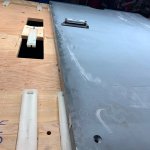

I expected MUCH worse... That looks better than 90% of the tables that I work on around here. From what I can see in the photos, it might take me 20-30 minutes to clean.Here are a couple pics. Kinda hard to show to much as they are stacked and leaning up on a wall. Suggestions? Thanks

Get yourself a Razor Scraper, and use standard utility blades. The 4" blades don't work as well. They are too wide, which leads to a number of issues.

To do a final clean up (including the wax), you can use mineral spirits (or Toluene, MEK, or any number of other chemicals) and a scotchbrite pad. You want to make sure that there isn't any glue residue left behind (or at least very little), as the new contact cement won't stick to it (assuming that the installer uses a roll-on type).

Be sure to wear the appropriate gloves. Each chemical requires a different glove material:

Mineral Spirits - Nitrile

MEK - Latex (limited use)

Toluene - Vinyl (limited use)

Additionally, before the slates are placed on the frame, you'll want to back off the slate levelers, such that they are below the surface of the frame.

Where are you located?

I guess I’m referring to the slate seams, and getting off the old Bondo, etc. I was not really thinking about a glue down Coin or Smart table where the cloth is stretched and glued down all the way around, using spray glue. I assume denatured alcohol or mineral spirits might remove it?Its pretty clear you have not actually done this. The amount of spray glue is ridiculous. That paper would keep gumming up, fact.

TFT

boogieman

It don't mean a thing if it ain't got that ping.

Personally, I'd hire someone to move it to the location and set it as my after work project. Dive deep into threads about pool setup and mechanics and just DIY. Is it a pain? Sure. But it could also be an activity for you and your sons to tackle.Hi guys. Im probably similar to a lot of you guys on here. Im a regular 47 your old dude with a family and a blue collar worker. Although I like to shoot some sticks I really just bought this table to enjoy with my now teenage kids and upcoming teenage kids. I really was trying to land a Gold Crown Iv but never seemed to have any luck finding one local enough to pickup. In my journey of searching I came across a tech who mentioned he just took apart a 9’ blue diamond for someone opening a hall who has one to many tables So I ended up picking up this table. Probably paid to much but it was nice, convenient and a ‘tech had already taken it apart. I ended up meeting the older gentleman who owned the table as well as a building he was renovating into a pool hall. He had several new Diamonds arriving sold sold the one I bought. He was a great guy and has helped my family indirectly through his work and was really a nice pleasure to meet. Anyway. That’s the short of it. Was hoping to get it setup today but seems no. Not really trying to bash as Trent did offer to buy back the felt I was planning on using with him so I would be happy to take him up on that thanks. So really no harm no foul again I just didn’t know what to expect and don’t want to bash anyone. I’m sure as the customer there is more I should have asked or known but truthfully I’m just a regular joe looking to get a pool table setup in my basement. I did contact the ‘tech’ who took it apart and he mentioned it was originally setup by a diamond tech and not him, he removed it from the another pool hall and moved it to the older gentleman I bought it from. I can’t speak to his work other then all the parts appear to be there. All I can say is hopefully moving forward I can get this setup and be done with it. Truthfully it’s turned out to be way more effort and cash then I ever planned and I’m really just disappointed and sorta regret my whole effort to get a new table at this point. Thanks for the warm wishes and everyone just keep doing their best

The ask the mechanics forum are very helpful for people who do research and ask the right questions. Sorry you have to deal with this, I get it, it's easier to hire a pro, but if the table is too out of whack it's not worth the effort. That's where DIY as a hobby/learning experience is great.

boogieman

It don't mean a thing if it ain't got that ping.

Razor blade paint scraper. Get plenty of spare blades and one with an ergonomic handle. It's a chore but one you can do. A heat gun might help melt/soften the glue.Here are a couple pics. Kinda hard to show to much as they are stacked and leaning up on a wall. Suggestions? Thanks

There should not be any "extra" visible/ bondo on the slates, its supposed to be a neat lil pink stripe in between the slates. Making a SEAM and not a BRIDGE. Neither of those will work on the solvent based adhesives. Scraping it off is a PIA....This is what I said about the adhesives before " I used to use Klean Strip Adhesive remover, they took out the methylene Chloride and now it barely works. It used to MELT the adhesive in minutes..... "I guess I’m referring to the slate seams, and getting off the old Bondo, etc. I was not really thinking about a glue down Coin or Smart table where the cloth is stretched and glued down all the way around, using spray glue. I assume denatured alcohol or mineral spirits might remove it?

I am not saying it could not be set up proper and level. I have no doubt that it could be made playable again. In my experience when the perimeters are randomly maxed out and the centers are to = very questionable slate.... All of it equals more and more time. IMO one of the worst situations in business: trying to re-negotiate the pricing with all the extra work with the customer while onsite. Especially add this simple fact: I just decided I didn't want to do it. There are plenty of other guys who will say: well I can do that in 20-30 minutes.... I don't believe that, but, I been wrong before!! I have also spent more time getting that adhesive off without a good adhesive remover than I want to admit and it sucks. They can have at it.As far as the adjusters being maxed out could be more about the last guy not knowing what he was doing than the slates being a problem, or the got moved somehow when it was dismantled and moved.

Could be wrong though.

I like FLAT slate. I am not saying Brunswick slate is "perfect", rather this: Its far far better and I never have to do all the Bull$shit that was going to be involved with the job in question. Again, I think the OP is a very nice guy, I was very respectful in giving my reasons for not wanting to do the job and left. Simple as that.

I don't do much service at all and prefer to only work on the tables I sold and that I installed. I know what I am walking into and I am very very comfortable with that.

This is the first time this has ever happened in all of my 10 years and surely will be the last Diamond service job I will ever take on. I was happyI could see all of this adding up to a nightmare and very happy with my decision to pass.

TFT

Last edited:

A quick search seems to turn up lots of roughly comparable products with Methylene Chloride (aka Dichloromethane) so if that really was the issue then it seems to be a pretty easy one to fix. If it was actually something else then perhaps you or someone else might be kind enough to use your experience to advise the OP on how best to use one of these readily available Methylene Chloride products because you seem to be saying that it is what one would want to use since it works so well for this particular task.I used to use Klean Strip Adhesive remover, they took out the methylene Chloride and now it barely works. It used to MELT the adhesive in minutes.....

Why is it that you will never sell or work on Diamond tables again? I read all your responses but it wasn't clear to me. Just curious.This is the first time this has ever happened in all of my 10 years and surely will be the last Diamond service job I will ever take on.

Curious how your situation is working out. There is a huge bright side to this. You have a 9’ blue label in your basementAdditional pics thank you for your help. Much appreciated

updated pics. Will send some of the completed table when I have time.

Attachments

-

E4CEDF1A-B4ED-4BEE-8324-2EE92D485D9D.jpeg263.1 KB · Views: 141

E4CEDF1A-B4ED-4BEE-8324-2EE92D485D9D.jpeg263.1 KB · Views: 141 -

BC553418-CC59-4D70-9385-2D6F2D4DD56C.jpeg266.6 KB · Views: 136

BC553418-CC59-4D70-9385-2D6F2D4DD56C.jpeg266.6 KB · Views: 136 -

B9F33365-8D89-4B12-A4C2-A47904F207A9.jpeg249.6 KB · Views: 132

B9F33365-8D89-4B12-A4C2-A47904F207A9.jpeg249.6 KB · Views: 132 -

6A33E000-9DE3-4AFF-9F15-3F5D741C1751.jpeg302.4 KB · Views: 126

6A33E000-9DE3-4AFF-9F15-3F5D741C1751.jpeg302.4 KB · Views: 126 -

22E35F1D-AB12-48A8-8FB4-29DC5742B679.jpeg162.5 KB · Views: 127

22E35F1D-AB12-48A8-8FB4-29DC5742B679.jpeg162.5 KB · Views: 127 -

00EB7872-D884-4256-8C93-5993B3592C5D.jpeg134 KB · Views: 141

00EB7872-D884-4256-8C93-5993B3592C5D.jpeg134 KB · Views: 141 -

8A7807D2-1BD3-4094-927B-CF2EA8754C2D.jpeg214.2 KB · Views: 136

8A7807D2-1BD3-4094-927B-CF2EA8754C2D.jpeg214.2 KB · Views: 136

Last edited:

Good for you and yours, glad it worked outHi. I just wants to wrap this up with the final of my story. First everyone thank you for the tips and well wishes, much appreciated. I was able to get another local company out that had experience with Diamond tables. I called around after my last tech decided it wasn’t for him. It just worked out that the team was able to visit the next day. Two young dudes in their mid 20’s showed up with a box truck loaded with tools and misc wood and gear. I asked if they wanted to come and check the condition of the table before unloading their tools. They said no need and went to work. I mentioned some of my concerns brought up by my previous visit and they didn’t seem to have any worries or concerns and their confidence brought me confidence. The slates didn’t seem to be an issue for these guys as he did a quick scrape and prep of the area and had no issues. He did agree the leveling system on these tables is challenging but not a real problem if you take your time and know what your doing.

I have to give some credit here to the two dudes that shows up though as they handled everything like a professional and met my expectations. One of the many differences I noticed between them and my precious tech was the chill factor. You ever have a tech out or service guy out for any industry, computers, HVaC, pool tables and the person on-site just constantly is bashing the competition? I never like and usually never go with the guy that comes over and dogs out everyone else while basically telling you how good they are. I’ve worked in service for many years in various fileds

And tried to never do that, let your work speak for itself. These guys even after hearing my story basically said yeah we’ve r heard it before and just went about their business. My previous tech when he first came down in my basement I had a video on how to install these diamond tables up on my tv so I kinda knew what to expect and he basically started bashing the guys on the video. That’s just not for me. All and all I think it worked out for the best for everyone. I did pay more then I was quoted by my first tech but it did include a second guy and took around 4-5 hours and really couldn’t be happier. I’ll include a pic of it completed as I’m really happy with it. Thanks again everyone