You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

buffing wheels

- Thread starter Dave38

- Start date

Looking for a supplier of buffing wheels and also, which wheels are the best? I just picked up a HF benchtop dual wheel buffer don't know which wheels to buy. I did some searching and got confused quickly

Any help is apprecieted,

DAve

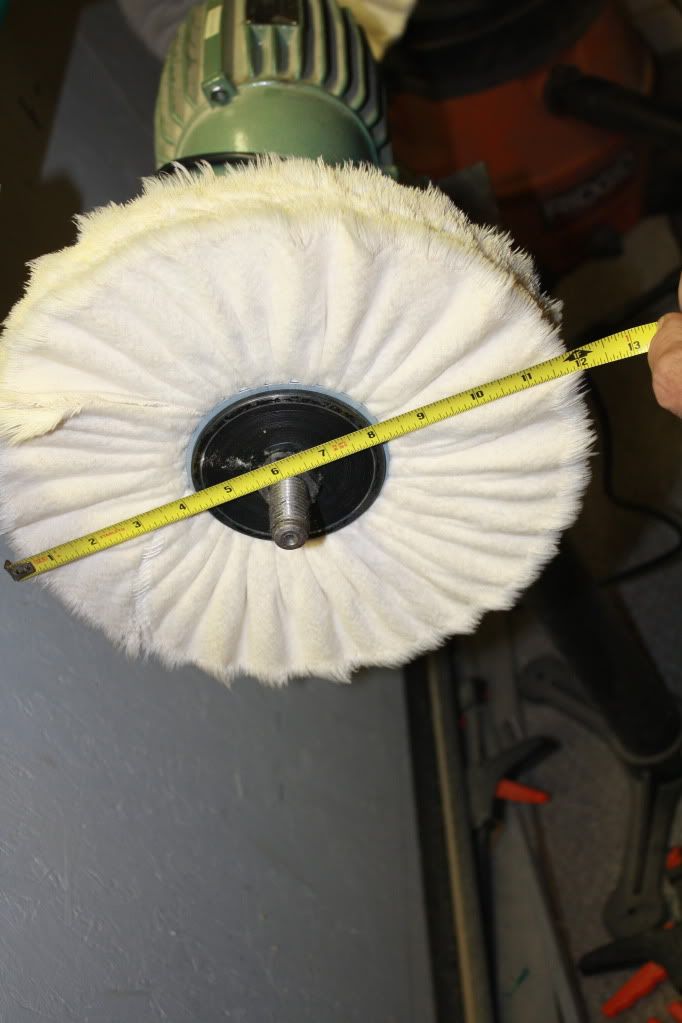

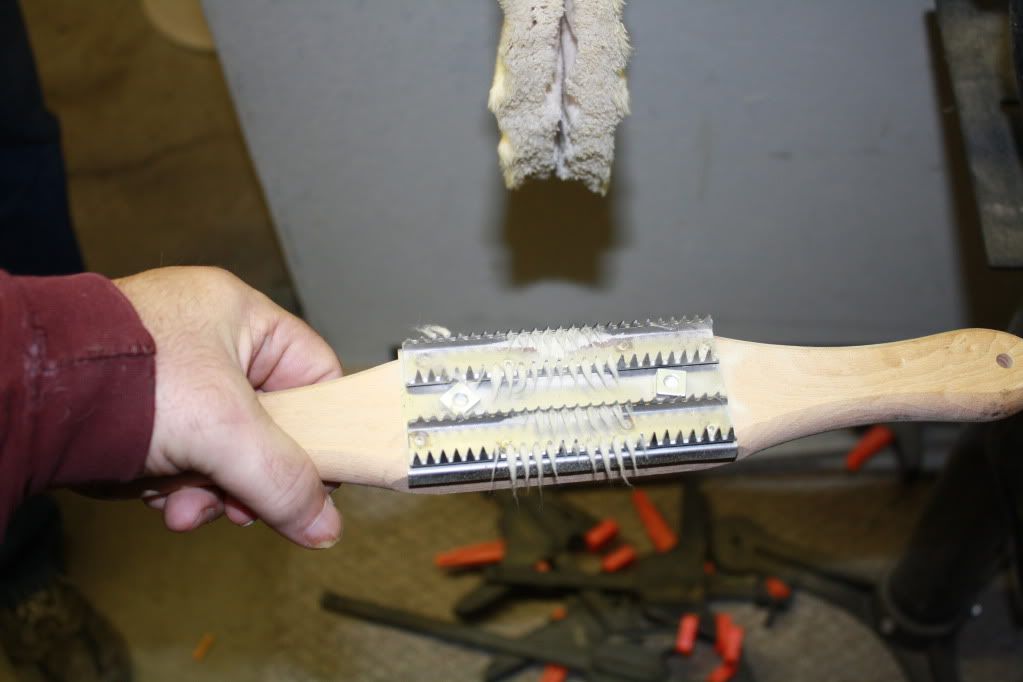

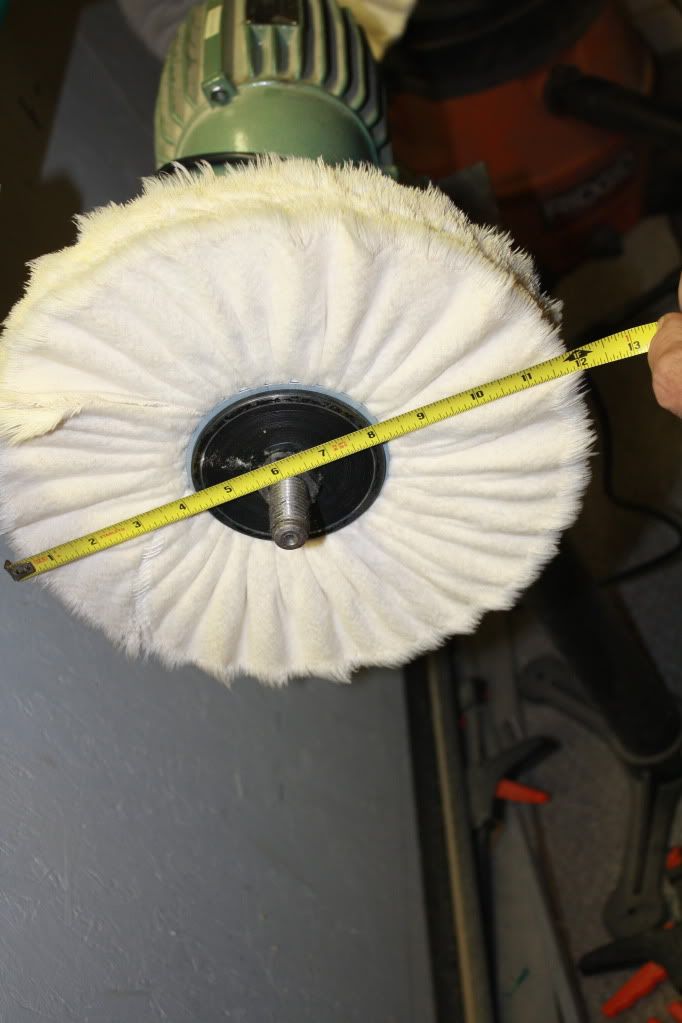

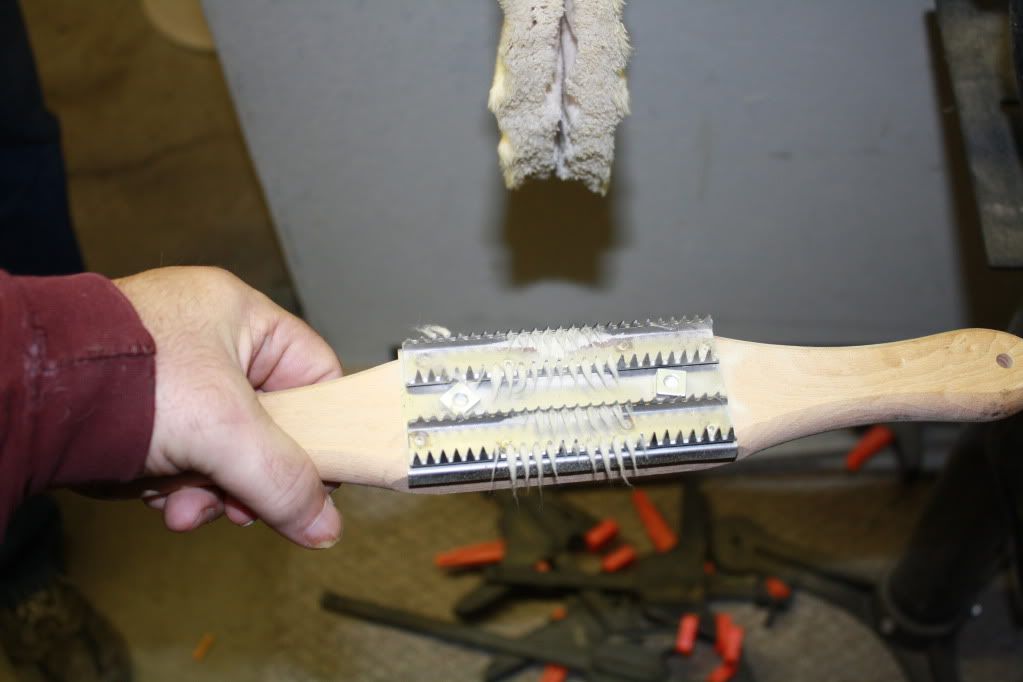

These are the ones that I purchased. I bought 8 of them. I put four of them together which made two, thicker wheels to make it easier to hold the cue against the wheels lengthwise so as not to get ring impressions when finished. I put them on a 2 foot piece of 3/4 all thread and would run it between centers on one of my variable speed lathes. The main problems that I had with them, however was that when running they would sling compound onto mt lathe's rails and it is so hard keeping them very clean from any dust that would stick to the compound on the wheels when not in use and cause small scratches.

http://www.grizzly.com/products/10-x-16-Ply-Final-Finishing-Buffy/T24288

I no longer use them however. I now use a 0-3000 rpm variable speed, revolving auto body finisher. I run the cue between centers on a slow speed and buff the cue at the very rim of the wheels. My buffer and wheels are velcro backed so I can change wheels quickly. I use 3 different and sometimes 4 different compounds. When not in use all of my wheels go into a plastic tub with a sealed lid.

Dick

Last edited:

Grizzly used to have a 3 wheel system that had 3 ea 10 inch buffer wheels on one rod. I purchased 5 or 6 years ago and then got a $125.00 wood lathe and put them on there. Use 3 different compounds and its done. You want 3 buffer wheels, one that is course, a medium and then a fine or very soft wheel to do the finish buff.

Hope that helps,

AB

Hope that helps,

AB

Like Dick, I use the automotive type buffer/polisher.

It's like a right-angle grinder except it turns at a much slower RPM.

Mine only has two spds and I always use the slowest.

I wet-sand to 3000 grit and most times only need one compound for

most of my production work. For 'the good stuff' I've got 3 compounds.

I use the foam buffing pads and hand-polish with a lamb's wool pad.

I can polish-out a shaft in way less than 5 mins.

KJ

It's like a right-angle grinder except it turns at a much slower RPM.

Mine only has two spds and I always use the slowest.

I wet-sand to 3000 grit and most times only need one compound for

most of my production work. For 'the good stuff' I've got 3 compounds.

I use the foam buffing pads and hand-polish with a lamb's wool pad.

I can polish-out a shaft in way less than 5 mins.

KJ

Hi,

I think you will find that this buffer @ 1100 rpm with a 12" is the right combo. Google Caswell Buffers and take a look.

Rick

I think you will find that this buffer @ 1100 rpm with a 12" is the right combo. Google Caswell Buffers and take a look.

Rick

I've been using the same Makita variable speed auto buffer since 1984. It is strapped upside down on a sturdy, cheap. padded wooden stool, has a long cord, a quick change velcro pad, 3 waffle foam pads and 3 different polishes. I just carry it outside the shop when I'm buffing and all the compound and dust stays outside.

Thanks for all the info guys, I apprecate it.

Rick, the wheel in your pictures, is that a caswell wheel? If so, which one? I was on their site a few days ago and that's when I realized I needed assistance, as there are way too many wheel types out there.

Dave

Rick, the wheel in your pictures, is that a caswell wheel? If so, which one? I was on their site a few days ago and that's when I realized I needed assistance, as there are way too many wheel types out there.

Dave