You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

BUMPER VS BUMPERLESS

- Thread starter bbb

- Start date

thanks for the replythe rubber bumper does tend to dampen vibrations slightly........... bumperless may seem crisper to some people

Kim

Back in the day it was marketed as "vibration damper" not bumper...

Someone requested a canvas phenolic "bumper" here once.Back in the day it was marketed as "vibration damper" not bumper...

So I made one . Stange. But, it sure looked pretty .

The end mill disagrees but it was pretty.

The end mill disagrees but it was pretty.

?

meaning?

I get the pretty part.

What say did the mill have in the conversation?

Wasn't that a lathe job anyway?

smt

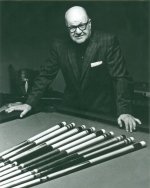

I like the look. Bumperless cues have a certain appeal. I have a few. But yes they have to be handled carefully. I only use mine on a carpeted floor. Here's cheers to Mr. Bumperless cues.

Attachments

Last edited:

I use 4-flute carbide end mill to turn canvas phenolic so it looks really clean.?

meaning?

I get the pretty part.

What say did the mill have in the conversation?

Wasn't that a lathe job anyway?

smt

Canvas phenolic is very abrasive and dulls cutters fast .

Aha!

Used to mil a fair amount of phenolic for machine parts and for long wearing forms for tracer apps.

But thinking back, most of it is/was probably linen. The good old stuff, lol. Have used carbide, but mostly HSS.

More recently, sometimes using canvas for cues because i like the visual texture, have ground it on the surface grinder with spindex, with mist coolant. Just like the rubber parts we discussed elsewhere, but faster.

smt

Used to mil a fair amount of phenolic for machine parts and for long wearing forms for tracer apps.

But thinking back, most of it is/was probably linen. The good old stuff, lol. Have used carbide, but mostly HSS.

More recently, sometimes using canvas for cues because i like the visual texture, have ground it on the surface grinder with spindex, with mist coolant. Just like the rubber parts we discussed elsewhere, but faster.

smt