just curious:

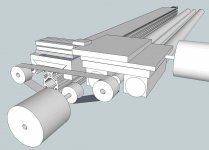

from the price I have seen for accurate glass slide rails, would it not be close to the same price, and in the future, more versatile, to just make a 2 axis CNC lathe out of the taper shaper? I have no experience making a cnc, but I have both a Taper Shaper and a CueMonster. They look, and measure, identical to me. I noticed a few tapped holes are added to the CNC machine and a few pieces are bolted on. Perhaps you should talk with the nice people at Unique? They offer an upgrade kit for the cuemonster, and possibly about half that kit and a few plates of aluminum predrilled and tapped by Unique will do the trick? Of course a controller and computer also, with appropriate software. Yes it is possible to do IMHO.

I would be very interested to hear how that works for you. I want to try the same thing, not because the Taper Shaper is not a good machine, I just see how much easier I can turn shafts with my Monster no matter what taper I have a whim to cut. And results with the CNC are so much more dependable. Best Wishes!