yea i really appreicate you guys answering so many questions. i believe im headed in the right direction. im just super meticulous when it comes to building something and i like to get the best results right away. i understand you guys have been through alot of trial and error and i know I will be faced with the same exact thing. Hopefully I will get a case done and post it up so you guys can give me some more advice. Thanks again!

Have you ever heard the term Paralysis by Analysis? You could never start if you try to think of all the angles first. This is why I posted the basic guide, start with the tools you have at hand.

Go to the hardware store and buy some plumbing tubes, a hacksaw and sandpaper. Make the tubes. Go to the fabric store and buy fabric you like. Take your cue in with you and see how it slides on the fabric, decide if you want your cue rubbing on the fabric. Feel the stretchiness, buy several types to try. You don't even need to sew the liners actually, you can overlap the edge and tape it down in such a way that it won't move. That is what I did on my first couple cases, it just takes more time to do.

After 18 years I have a certain way I like to do the interiors. I have them measured out to accommodate in an easy to use way, just about every cue length except the odd ones that are very short or very long. Most cue case makers don't see the need to do it the way I do it and they sell well and receive high praise. So don't be too obsessive about it at the beginning. Get the basics down and modify from there.

I would start with a 1x2. Use cardboard to mock it up as Billiardshot said to do. I make paper models ALL THE TIME. When we are working out a problem in my shop my desk looks like kindergarten with scotch tape and scissors and paper cutouts - you will be surprised how much you can learn by doing real world modeling like this. I have worked out problems this way in minutes that I couldn't do in hours of trying on CorelDraw.

MAKE NOTES as you go. DON'T LOSE THEM. Keep a notebook. I have drawings and notes that I refer to from 1991 on my laptop.

Do you know why Jack Justis can make 100+ cases a year out of his laundry room? He stays off the forums

AND he has a system down that works for him, everything he does is done to set patterns, not unlike a factory. This is what everyone from individual case maker to giant factory does who makes repeated items. Anyone who only makes true unique pieces is literally making a prototype each time. BUT even a Picasso repeats elements because it's human nature to draw on what you have learned to create the new.

Here is the thing, if you look at Jack's early cases you will see that the style is much different, the work was not as tight, he was experimenting and learning. Eventually the cases developed into the signature look that they have today.

And you can see the same thing with just about every case maker's early work. There is no way that we can make you into a full fledged case maker even if we write a detailed tutorial. The only way to get there is to start.

Confucious or some Chinese philosopher said "a journey of a thousand miles begins with the first step."

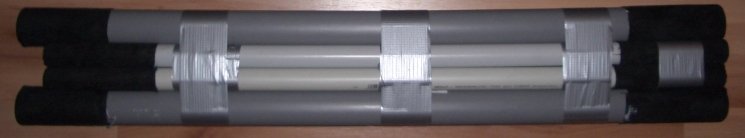

Hell I saw a guy in Valley Forge last year with a Duct Tape and Newspaper case. He had made a cigar-case style pool cue case out of rolled newspaper and duct tape and it was not only very functional it was very unique and kind of cool. Not $400 worth of cool for me though which is the price he asked for when I asked if he wanted to sell it. The funny coincidence was that on the way home I saw Duct Tape wallets for sale in the airport.

Wrap that cue and get to it.