You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Custom cues made in Philippines

- Thread starter Alx

- Start date

I have three Audricks that I bought in 2007. All three are still perfectly straight. Two of them have piloted steel joints and they play well, I like the way they hit, but I usually play a JOSS. Similar joint, so it makes some sense. One of them I got with a flat faced joint, and I don't like the hit, but that's the wife's cue.

I did a bit of a review on Audricks back in 2007 on Ebay. I updated it a couple of times but not recently. They spend their time in the closet. For now they are keepers. Occasionally I do take them out to shoot. When my wife shoots she uses her Audrick.

Some have said that repairs are a problem, that costs escalate. I am really curious as to what exactly might have happened to drive up a repair cost.

I did a bit of a review on Audricks back in 2007 on Ebay. I updated it a couple of times but not recently. They spend their time in the closet. For now they are keepers. Occasionally I do take them out to shoot. When my wife shoots she uses her Audrick.

Some have said that repairs are a problem, that costs escalate. I am really curious as to what exactly might have happened to drive up a repair cost.

Some have said that repairs are a problem, that costs escalate. I am really curious as to what exactly might have happened to drive up a repair cost.

Repair prices are based on time. I have my prices set on the average time it takes for a given repair, similar to an auto mechanic. If a cue come in and I know that it will take longer than the set average time, I need to adjust the cost due to the added time involved in the repair.

I understand that.

What I am getting at is finding out what exactly might be involved that escalates the time involved in repairs on such a cue. What kind of repairs? What kind of problems come up related to the construction, materials, or design of the cue that increase the repair time?

What I am getting at is finding out what exactly might be involved that escalates the time involved in repairs on such a cue. What kind of repairs? What kind of problems come up related to the construction, materials, or design of the cue that increase the repair time?

What kind of problems come up related to the construction, materials, or design of the cue that increase the repair time?

Two things need to be understood before I explain this. One, I am speaking in generalities, not about cues from the Philippines or any one maker or country, in particular. Two, the cues I see have problems. That's why I have them.

-Cues may have a pin/insert the is not concentric to the axis of the cue.

-Collars that have "popped" due to the material they are made from or unseasoned wood.

-Warpage

-Inconsistent tolerances

-Inferior materials, in general

-Uneven finish application

That's off the top of my head but each poses a unique issue when working on a cue.

I see, I suspected such things, I was just hoping for some more specific input about what comes up that you don't expect that would increase the time of the repair.

From what I hear you are the go-to guy for Meucci Originals resorations, and I need one done. Note to self- don't try to send my Audrick shaft for a tip at the same time lest the ferrule disintegrate on the lathe. Would that be an accurate assumption? (exagerration intended :smile: )

From what I hear you are the go-to guy for Meucci Originals resorations, and I need one done. Note to self- don't try to send my Audrick shaft for a tip at the same time lest the ferrule disintegrate on the lathe. Would that be an accurate assumption? (exagerration intended :smile: )

Two things need to be understood before I explain this. One, I am speaking in generalities, not about cues from the Philippines or any one maker or country, in particular. Two, the cues I see have problems. That's why I have them.

-Cues may have a pin/insert the is not concentric to the axis of the cue.

-Collars that have "popped" due to the material they are made from or unseasoned wood.

-Warpage

-Inconsistent tolerances

-Inferior materials, in general

-Uneven finish application

That's off the top of my head but each poses a unique issue when working on a cue.

Four or five years ago I fixed well over one hundred shafts for a dealer friend of mine because they were suffering from some of the above. They came from some foreign country

also mentioned somewhere above.

Mario

Four or five years ago I fixed well over one hundred shafts for a dealer friend of mine because they were suffering from some of the above. They came from some foreign country

also mentioned somewhere above.

Mario

Mcues...... I know this is off topic and sorry for that to the OP, but Mario, from an avid aquarium owner, those are some BEAUTIFUL discus in your avatar, that is one of the hardest tropical fish to raise, they are gorgeous.

Now.... back on topic.

Mcues...... I know this is off topic and sorry for that to the OP, but Mario, from an avid aquarium owner, those are some BEAUTIFUL discus in your avatar, that is one of the hardest tropical fish to raise, they are gorgeous.

Now.... back on topic.

Those were my F4's from the breeding line I developed.

Mario

i have 37 of em

I have 37 of these cues ready to ship , i had 40 sold 2 to a customer and sent one off to nick S free of charge for a review.

Im sure that some of these cues have had a bad name in the past but they sure have got their shit together since.

Im not a cue expert by any means , but these cues look amazing , are finished beautifully and are as straight as an arrow.

Im selling them at rock bottom prices , so please look out for Nicks review here and then i hope we can do some business.

I assure you that Nicks opinion will be completely neutral , to prove this here is a part of the letter i sent him with the cue :

In your review I would ask that you are completely neutral and in addition to your own review topics if you don’t mind could also include the following.

• The way the cue was packed for shipping

• Value for money

• Best customer type the cue would suit etc

• Look , feel , play and so on

• I would like to leave it to you and maybe you already have thought about the topics I have listed but I thought id note them anyway just to be sure.

Anyway lets just wait and see , im as curious as you all are, also quietly confident that these cues will get a good review.

Cheers

Eamonn

I have 37 of these cues ready to ship , i had 40 sold 2 to a customer and sent one off to nick S free of charge for a review.

Im sure that some of these cues have had a bad name in the past but they sure have got their shit together since.

Im not a cue expert by any means , but these cues look amazing , are finished beautifully and are as straight as an arrow.

Im selling them at rock bottom prices , so please look out for Nicks review here and then i hope we can do some business.

I assure you that Nicks opinion will be completely neutral , to prove this here is a part of the letter i sent him with the cue :

In your review I would ask that you are completely neutral and in addition to your own review topics if you don’t mind could also include the following.

• The way the cue was packed for shipping

• Value for money

• Best customer type the cue would suit etc

• Look , feel , play and so on

• I would like to leave it to you and maybe you already have thought about the topics I have listed but I thought id note them anyway just to be sure.

Anyway lets just wait and see , im as curious as you all are, also quietly confident that these cues will get a good review.

Cheers

Eamonn

brighthorizon

Registered

I have 2 from this seller

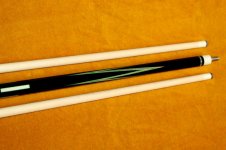

Here are mine.

The one on the right is my jump cue. Both are straight, have 2 shafts for each and hit nice. Compared to my other customs from Ray Schuler and Bob Meucci, which are quite a bit pricier, the play is great not to mention the price.

Besides its not the stick that wins its the player behind the stick.

Has anyone bought or know anything about the custom cues on ebay from the phillipines? Like these...

http://cgi.ebay.com/Wholesale-Lot-3...880?pt=LH_DefaultDomain_0&hash=item2a10900710

http://cgi.ebay.com/ws/eBayISAPI.dl...=bBxXQpYJ%2BdEyAcg%2FiJaYhLixtLM%3D&viewitem=

Here are mine.

The one on the right is my jump cue. Both are straight, have 2 shafts for each and hit nice. Compared to my other customs from Ray Schuler and Bob Meucci, which are quite a bit pricier, the play is great not to mention the price.

Besides its not the stick that wins its the player behind the stick.

Attachments

I have several floating around here. All were from the lower quality builders from years back. The quality was deifintely not there. Now you have Bebot Bautista and Black Pearl Cues and a few others that are doing higher quality work. So you have to go with a known quality maker over there or you will probably wind up with a fancy cue that is poorly made.

I have only one custom from there (it's my brothers cue but he don't like it, so he gave it to me) and it's not from the top cue maker like Bebot, Linds, etc. IMO, their detail is not so good as the top cue maker, it's deflect more, but it plays well. So i suggest to buy from the top cue maker, except you ever play with the one that not from the top list and love it, once again it's just my opinion. I send that cue to be modified and refinished by some of indonesian top cue maker, and now it looks and plays lot better than before.

Last edited:

I bought this cue from Joel Davidas and it seems to be pretty good. Hits solid, workmanship is good.

The other cues you see on eBay with all the abalone an inlays seem to not be too good. My friend has one that doesnt joint together correctly. Its almost 1/8" offcenter

The other cues you see on eBay with all the abalone an inlays seem to not be too good. My friend has one that doesnt joint together correctly. Its almost 1/8" offcenter

Attachments

Here are mine.

The one on the right is my jump cue. Both are straight, have 2 shafts for each and hit nice. Compared to my other customs from Ray Schuler and Bob Meucci, which are quite a bit pricier, the play is great not to mention the price.

Besides its not the stick that wins its the player behind the stick.

I'd rather see the fancy Schuler.

I had a viattorre that I traded and wish I didn't. The cue I traded for wasn't as nice  . Anyway I'd like to get the viattorre back. I didn't care for the shafts so I had the ferrule replaced on the straight one and a 314 made as a second shaft. Miss the cue.

. Anyway I'd like to get the viattorre back. I didn't care for the shafts so I had the ferrule replaced on the straight one and a 314 made as a second shaft. Miss the cue.