Each to his/her own, but for sake of escaping the writing of another book here, I won't even waste space with My thoughts on other woods. I don't disagree with everything that has been said when referring to other woods, but I thought We were talking about about the coloring of purple heart here, and My experiences with It has been that I don't need to seal It between every turn, especially where handle wood is concerned. If someone wants to, then I suppose It doesn't hurt. I just haven't found It to be necessary in My situations. There may be a little of a gray area when talking about PH shafts though, as when turned that small, I have on occasion been witness to very minute amounts of movement, but very rarely have I seen any with larger diameters. I wish all woods were as stable and easy to work with. I think everyone should experiment and find what works for them, because what works for one may not be same same for another, and every species has It's own characteristics.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Cut the Purple right off the Purpleheart!

- Thread starter GrimmCustomCues

- Start date

If I had a 75* 45% 24 hours a day, I wouldn't trust the shafts from moving

while they're on a plane on the way to Singapore or Taiwan.

One of the biggest names in cues is widely accepted there

to show some wobble in their shafts. They do have a curved taper so that wobble is magnified.

Their shop has to be

totally climate controlled bc of where they are.

Totally controlled shop and magic dip like nelsonite work for some though.

I prefer to let my woods endure the full effect of all four seasons, just so I can cull the squirrely ones. It's funny seeing a shaft move in spring, then straighten back up by fall, without ever doing a thing to it. When I first moved to the desert I ran a humidifier & tried keeping a constant temp. Didn't take long to quit that nonsense!

As for purpleheart turning brown after a cut, it's typical. I put a finished cut cue in the sun for an hour or so before finishing. Sometimes I use an industrial heat gun while the wood is spinning and run the heat up & down slowly. Turns very deep purple. Tried putting some under a UV light once but it didn't do anything.

SSDiver2112

Escott Cues

I know this is an old post, but after seeing it I decided to ask a related question I have been wondering about.

Because the Purpleheart I have worked with has been very inconsistent in its purpleness, I found baking it at 350 degrees will bring it back to a deep purple color. Vary the time to reach the shade you want. The color is consistent all the way through if it is cut.

Could this be done to a cue either as a blank or finished? I am assuming it could cause warpage and/or degrade the glue, but I just wanted to see if anyone knew or tried before.

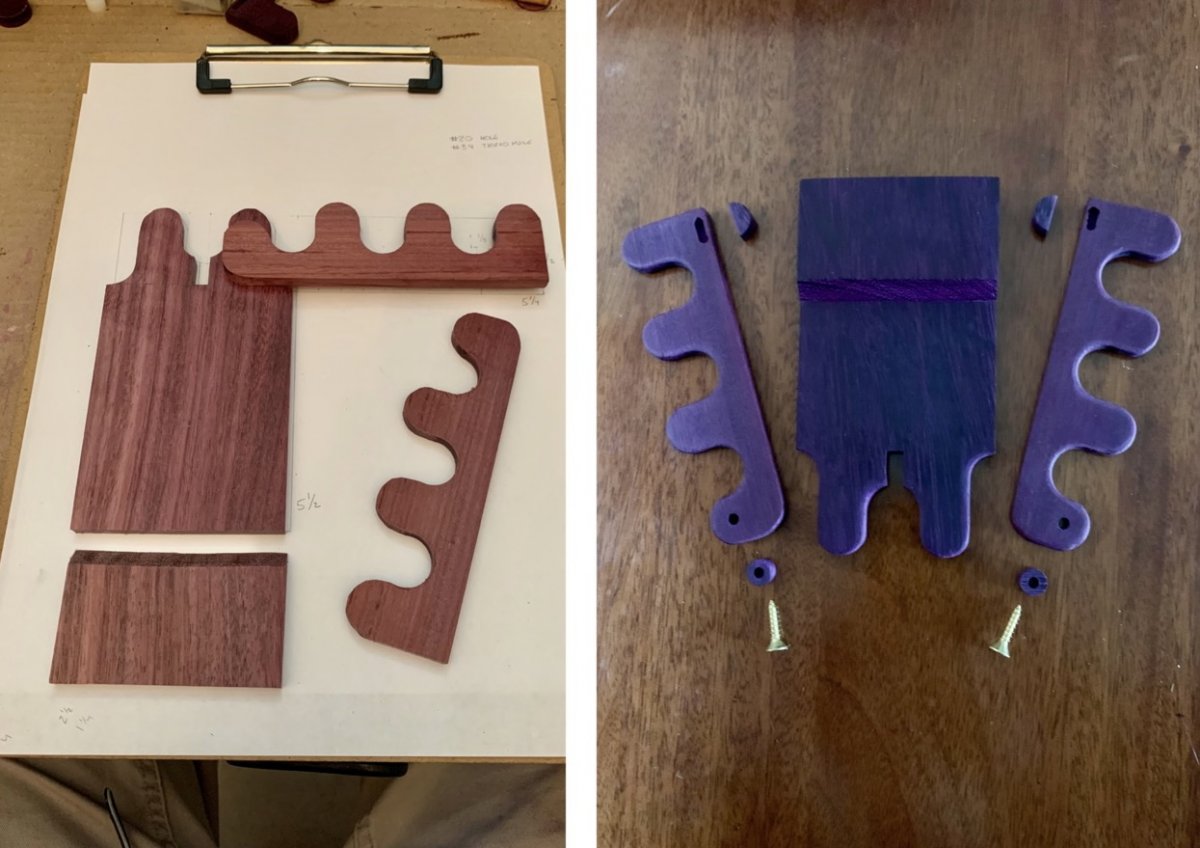

Before and After:

Because the Purpleheart I have worked with has been very inconsistent in its purpleness, I found baking it at 350 degrees will bring it back to a deep purple color. Vary the time to reach the shade you want. The color is consistent all the way through if it is cut.

Could this be done to a cue either as a blank or finished? I am assuming it could cause warpage and/or degrade the glue, but I just wanted to see if anyone knew or tried before.

Before and After:

Last edited:

boogieman

It don't mean a thing if it ain't got that ping.

I've seen purpleheart used on a butt and it was scorched with a torch. That and ebony. It was beautiful.I know this is an old post, but after seeing it I decided to ask a related question I have been wondering about.

Because the Purpleheart I have worked with has been very inconsistent in its purpleness, I found baking it at 350 degrees will bring it back to a deep purple color. Vary the time to reach the shade you want. The color is consistent all the way through if it is cut.

Could this be done to a cue either as a blank or finished? I am assuming it could cause warpage and/or degrade the glue, but I just wanted to see if anyone knew or tried before.

Before and After:

View attachment 637312

View attachment 637315

SSDiver2112

Escott Cues

Tried my hand at making some joint protectors. Once again just below the surface we get the brown wood. Of course, it can be left out for a while and the surface will turn more purple, but it will never reach the dark purple I want. I baked them for about thirty minutes which brought out the color I was looking for.

The good thing about baking it, is that the color goes all the way through so you can't "cut off the purple".

I learned that I should bake it before doing the final turning. I got them to the right diameter, separated the two parts and drilled, bored, and tapped it. After baking they shrank a little, so the diameter is a tiny bit smaller, and I had to re-bore and tap it to fit again.

The good thing about baking it, is that the color goes all the way through so you can't "cut off the purple".

I learned that I should bake it before doing the final turning. I got them to the right diameter, separated the two parts and drilled, bored, and tapped it. After baking they shrank a little, so the diameter is a tiny bit smaller, and I had to re-bore and tap it to fit again.

Last edited:

skiergd011013

Well-known member

Purpleheart has become my favorite cue wood. I just had this made a few months ago, and am having another one made right now.

Shorty Cues

New member

How lucky we the readers here. To get to hear great advise,, and knowledge from some great people who advice here. I remember back in the 80's how there was a tight nit group of cuemakers who were very careful to open up advise to people wanting to learn some tips. With respect thanks for taking time to answer. Benny