The reason to enclose it fully is to get the fine dust that you cannot see. An open frame like yours will catch the larger particles, but will still have a large amount of very fine dust (about .5 - 1 micron) floating thru the air that wont show on the surfaces until it builds up enough, but will cause a serious health issue. A handy tool to have is the one that measures the particules in the air. An example is:http://www.pmeasuring.com/particleC...15406d177ba5&gclid=COu_-O3k77gCFUyk4Aod9D8Afg

Measuring when nothing is running and then measuring once you start to cut, it's amazing the amount it increases and yet you can't see them...

Dave

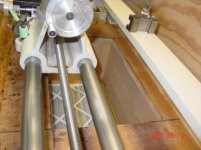

Thank you for the link to that device, I will be sure to look into that. As to the fine dust I will have to disagree with you. After a full day of turning shafts I don't get the fine dust accumulation on any surfaces in the shop. It is my belief that as long as your suction is sufficient to redirect the dust you do not need to have a full enclosure. I capture the dust as it is coming off the cutter, location of your inlet is key Of coarse I do not have that device you have linked to so I can not qualify with 100% certainty that my theory to be correct. I am curious now. When all is said and done regardless of how good your dust control is wearing a good mask is the only sure way of being certain you are safe.