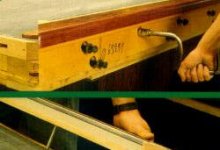

is there a torque value recommended for tightening t-rail bolts on an old brunswick? is there something you use to keep the bolts from loosening? also are washers necessary to put behind each bolt?..

gerald 901 412 9618 gmillioni@yahoo.com

gerald 901 412 9618 gmillioni@yahoo.com