I have a limited number of gun drills from a business that sadly closed in my area. They are brand new and size that I like to use: 18mm, or 0.7085 inches. I always found the 3/4 a tad large and the 5/8 small for my liking. The drills are 13 inches long depth of cut, & 7 inches of metal before you get to the ground 25mm shank area. Very easy to cut to different shank for anyone with a decent metal lathe. The current air feed is in the rear, but also simple to plug and side drill for a new entry point. I am offering these for $65.00 each shipped free to the USA. Remember they are brand new, sharp, and way overkill for our needs to cut wood.

Here is something I copied from Star's website about their drill bits, amazing!

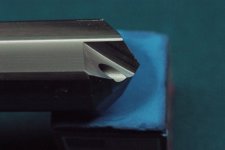

Star SU Single Flute Gundrill: Used as a general-purpose

tool in most drilling applications to obtain hole sized within .001”,

run-out requirements of .001” per inch, straightness of .001”

per foot. This tool is a single fl ute 3 piece contructions design

and has the deepest fl ute channel, thus enabling maximum chip

evacuation. Diameters are available from .0781 - 1.5”.

Here is something I copied from Star's website about their drill bits, amazing!

Star SU Single Flute Gundrill: Used as a general-purpose

tool in most drilling applications to obtain hole sized within .001”,

run-out requirements of .001” per inch, straightness of .001”

per foot. This tool is a single fl ute 3 piece contructions design

and has the deepest fl ute channel, thus enabling maximum chip

evacuation. Diameters are available from .0781 - 1.5”.

Last edited: