How do you install tips?

1) face off ferrule

2) sand ferrule (area to be glued ) 100 grit sand paper

3) removed

4) sand tip 100 grit sand paper

5) tape ferrule up to edge where tip is glued

6) Glue on tip Loctite Super Glue gel

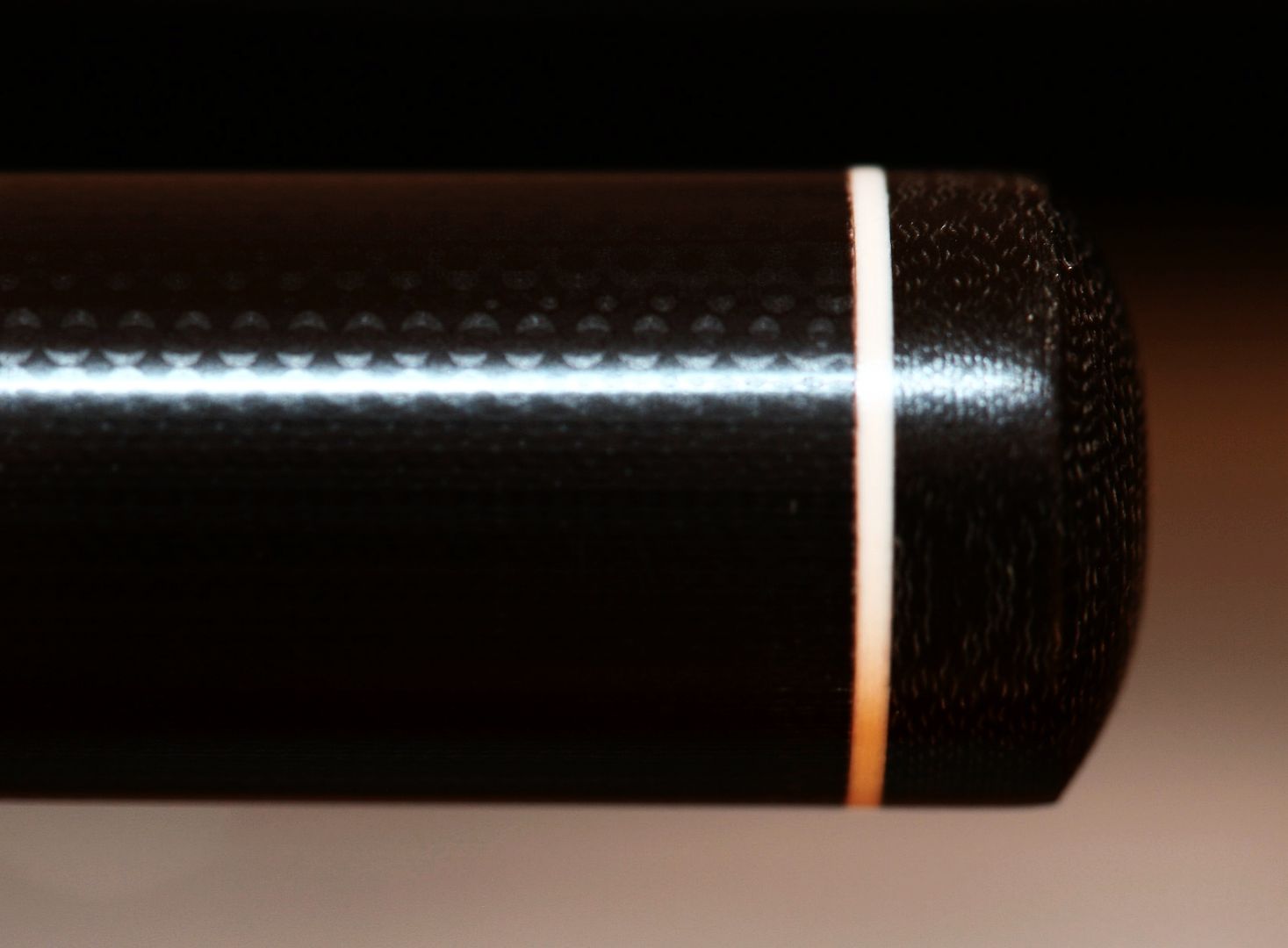

7) Trim sides of tip

8) shape tip to dime curve (quarter curve for break tip)

9) clean up ferrule (remove light scratches/ chalk marks)

10) 400/600/800 grit smooth out tip/ferrule

11) black marker tip sides -Not sure if this is ok to do?

12) coat of wax

13) buff

14) light scuff tip

15) chalk up tip

MODIFIED!!! list

IS it wrong to use utility knife to make light groves in tip and ferrule? YES!

Do not do that Dumb shit Sax!!!!!

How do YOU Install Tips?

jsaxman

Any feedback is welcome....

all ways ....looking for better way to refine....how to install tips!!!!

1) face off ferrule

2) sand ferrule (area to be glued ) 100 grit sand paper

3) removed

4) sand tip 100 grit sand paper

5) tape ferrule up to edge where tip is glued

6) Glue on tip Loctite Super Glue gel

7) Trim sides of tip

8) shape tip to dime curve (quarter curve for break tip)

9) clean up ferrule (remove light scratches/ chalk marks)

10) 400/600/800 grit smooth out tip/ferrule

11) black marker tip sides -Not sure if this is ok to do?

12) coat of wax

13) buff

14) light scuff tip

15) chalk up tip

MODIFIED!!! list

IS it wrong to use utility knife to make light groves in tip and ferrule? YES!

Do not do that Dumb shit Sax!!!!!

How do YOU Install Tips?

jsaxman

Any feedback is welcome....

all ways ....looking for better way to refine....how to install tips!!!!

Last edited: