I gave this machine to my father. I was just curious though, could this sort of machine be useful in a cue making shop?

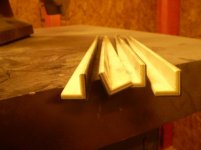

Its 2 HP and has 1/4" & 1/2" collet. The motor can be mounted above the table (pictured) or below the table. The foot peddle moves the table upward for pin routing.

Its 2 HP and has 1/4" & 1/2" collet. The motor can be mounted above the table (pictured) or below the table. The foot peddle moves the table upward for pin routing.