I just purchased a cheap basic lathe from a fellow AZer and it is fine and dandy but when I put it on my bench the foot pedal doesnt reach the ground. It has like a tiny sewing machine motor on it as it is. Is it possible to scrap the stupid pedal and get a some kind of a switch for speed settings to run continuously with the flip of switches? Does anyone have anything like that for sale? - and possibly a little nicer motor? (or advice?)

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Lathe question..?

- Thread starter bearsafety

- Start date

I just purchased a cheap basic lathe from a fellow AZer and it is fine and dandy but when I put it on my bench the foot pedal doesnt reach the ground. It has like a tiny sewing machine motor on it as it is. Is it possible to scrap the stupid pedal and get a some kind of a switch for speed settings to run continuously with the flip of switches? Does anyone have anything like that for sale? - and possibly a little nicer motor? (or advice?)

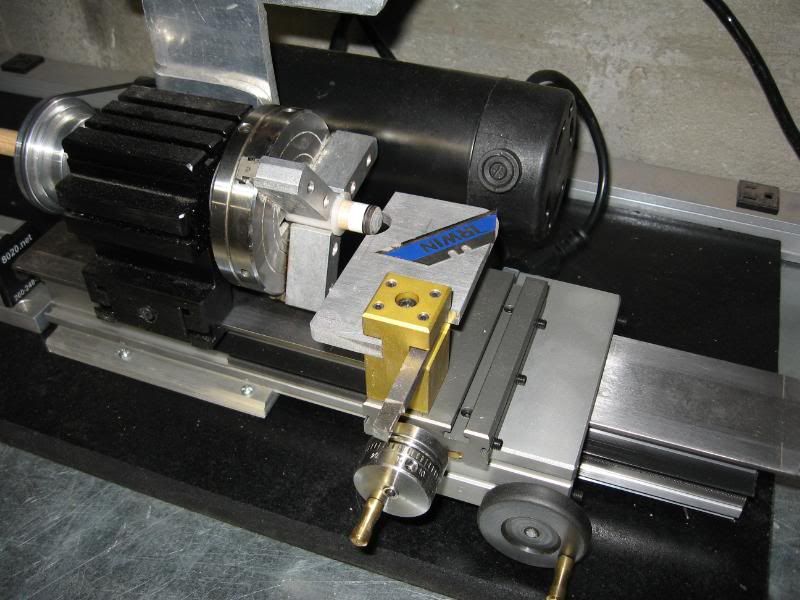

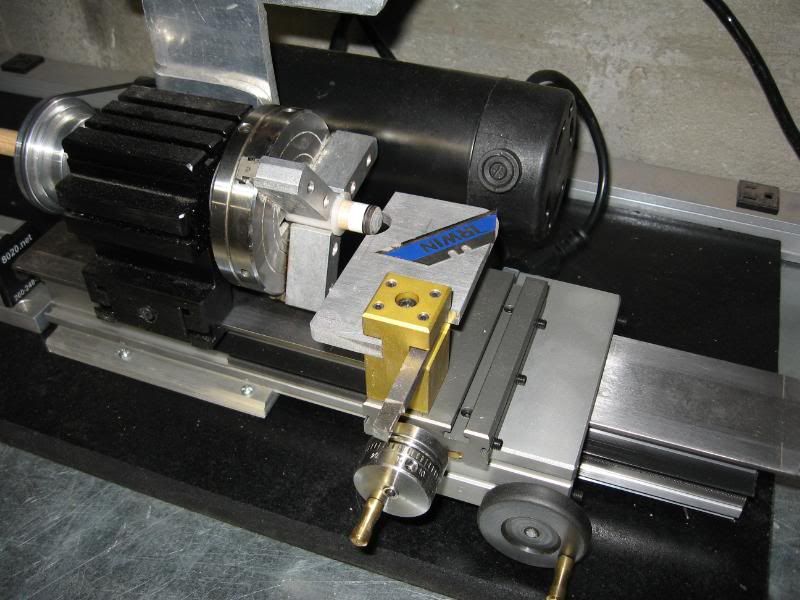

I can help you out with that, if your lathe has the black taig headstock, I can sell you my powerful 1/3hp dc motor with speed control and custom mounting bracket $165 shipped

Here is a picture of what I an talking about, if your set up is different, just post some pictures and I will see if I have anything that fits

Regards

Bassel

248-884-4469

Yes you can change it with a router variable speed switch.

One question. Are you talking about the drive motor or the add on wrap motor for the Hightower? You need to use both hands when spinning linen. The foot switch is a must to stop the lathe when something goes wrong.

One question. Are you talking about the drive motor or the add on wrap motor for the Hightower? You need to use both hands when spinning linen. The foot switch is a must to stop the lathe when something goes wrong.

Like this?- http://cgi.ebay.com/Variable-Speed-...962?pt=LH_DefaultDomain_0&hash=item4cec631532

And mr. Custom I would like to have that but i cant quite afford that much of an upgrade at this point in time. Ty though.

And mr. Custom I would like to have that but i cant quite afford that much of an upgrade at this point in time. Ty though.

or this? - I have no clue about any of this stuff.. but i like inexpensive!

http://cgi.ebay.com/Variable-Speed-...605?pt=LH_DefaultDomain_0&hash=item587e449405

http://cgi.ebay.com/Variable-Speed-...605?pt=LH_DefaultDomain_0&hash=item587e449405

Either one. As long as the motor runs with variable speed they all work.

I just purchased a cheap basic lathe from a fellow AZer and it is fine and dandy but when I put it on my bench the foot pedal doesnt reach the ground. It has like a tiny sewing machine motor on it as it is. Is it possible to scrap the stupid pedal and get a some kind of a switch for speed settings to run continuously with the flip of switches? Does anyone have anything like that for sale? - and possibly a little nicer motor? (or advice?)

Your use of the word 'stupid' to describe your foot-pedal implies that at some point it was capable of being intelligent.

So just how stupid is your pedal???

I think your approach to your problem is skewed.

You don't need another rheostat, you already have one in the foot-pedal.

What you need is to extend the cord so that it reaches the floor.

If this is a typical sewing machine foot-pedal it has a standard 2-wire cord.

Either replace the cord with one of a longer length or splice-in the extra length needed.

Should cost you all of a dollar.

We all like inexpensive but to spend 20 to save 2 doesn't quite make sense.

Your use of the word 'stupid' to describe your foot-pedal implies that at some point it was capable of being intelligent.

So just how stupid is your pedal???

I think your approach to your problem is skewed.

You don't need another rheostat, you already have one in the foot-pedal.

What you need is to extend the cord so that it reaches the floor.

If this is a typical sewing machine foot-pedal it has a standard 2-wire cord.

Either replace the cord with one of a longer length or splice-in the extra length needed.

Should cost you all of a dollar.

We all like inexpensive but to spend 20 to save 2 doesn't quite make sense.

Thanks for the help Einstein, its called a figure of speech.

Your use of the word 'stupid' to describe your foot-pedal implies that at some point it was capable of being intelligent.

So just how stupid is your pedal???

I think your approach to your problem is skewed.

You don't need another rheostat, you already have one in the foot-pedal.

What you need is to extend the cord so that it reaches the floor.

If this is a typical sewing machine foot-pedal it has a standard 2-wire cord.

Either replace the cord with one of a longer length or splice-in the extra length needed.

Should cost you all of a dollar.

We all like inexpensive but to spend 20 to save 2 doesn't quite make sense.

This is what I was going to suggest as the cheapest option to give more length to reach the ground.. Like mentioned most of the pedals are just a simple 2 wire power cord, and some extra length could be added easily enough. If You had a old cord off of something that doesn't work, or a cheap extension cord, then one could salvage the wire needed from that, and the fix could cost as little as nothing. Have to make sure the wires are secure, even by soldering, or an easier way is to use wire lugs, but either way they need to be taped up very well afterward, so that they can not touch each other, and the wire connections can't pull apart. Heat shrinking them may not be a bad Idea either.

I actually have 2 motors on Mine, a variable speed drive motor that operates via a toggle switch for normal operations, and a smaller motor with pedal for wrapping. As already mentioned for wrapping You want the pedal on there.

Thanks for the help Einstein, its called a figure of speech.

Actually it's inappropriate use of the language.

The pedal is incapable of any degree of intelligence so it is neither smart nor stupid.

It's incumbent on the owner/operator of said pedal to give the pedal commands,

assuming the operator has a sufficient level of intelligence to issue those commands.

However, from what I've read up to this point, I'm betting on the pedal.

Thanks for the help Einstein, its called a figure of speech.

.....................nevermind

Actually it's inappropriate use of the language.

You have to fix Stupid pedals with Stupid electrical cord.

Stupid cord is hard to come by these days and there are no cross over numbers for it.

Actually it's inappropriate use of the language.

The pedal is incapable of any degree of intelligence so it is neither smart nor stupid.

It's incumbent on the owner/operator of said pedal to give the pedal commands,

assuming the operator has a sufficient level of intelligence to issue those commands.

However, from what I've read up to this point, I'm betting on the pedal.

Are you serious? Do you want to have an intelligent conversation with people or pick on how someone uses a figure of speech. Get a life. I was Explaining in a hurry what I was working with and what I was looking for. Isnt slandering frowned upon on here? - Especially from such a respected "cuemaker" as someone like yourself..

I just purchased a cheap basic lathe from a fellow AZer and it is fine and dandy but when I put it on my bench the foot pedal doesnt reach the ground. It has like a tiny sewing machine motor on it as it is. Is it possible to scrap the stupid pedal and get a some kind of a switch for speed settings to run continuously with the flip of switches? Does anyone have anything like that for sale? - and possibly a little nicer motor? (or advice?)

Just so I understand it right, you have bought a lathe with a foot pedal that the cord doesn't doesn't reach the floor, and you are going to use it to work on cues? From your little bit of info, and no pictures, one would assume that is what you are doing. and that is the issue. If so, then I will state the following, If you can't figure out a solution to this issue on your own, then PLEASE don't work on anyone's cue. You won't be able to fix the F'ups that will occur. You left out some important info, like are you doing wraps, ferrule or tip work, shaft cleaning sanding, etc. How can someone recommend or give advice on a motor with a foot pedal if you leave out the details? The people that have responded so far have been quite kind in their wording. Even KJ's response, he was actually trying, in a nice way, to get you to think, as that ability is a requirement in this business, but that seemed to go over your head and you only caught his reference to your 'stupid motor' comment. I on the other hand, am usually more blunt. So I will be more to the point, If you can't figure this simple problem out, what will happen when you work on someone's $300 -and up cue and F it up due to a simple 'issue'?

In this business, if you have to ask how to make a short cord reach your foot, then hang it up as you don't have what it takes. Not being mean, nor trying to be an azz, just being real. You ask a question, that before asking it, most others would have already tried the above suggestions. Then you insult a guy that, blindfolded, and 2 hands behind his back, can do a ferrule and tip change on a predator cue quicker that most can tie their shoes.

IMO, before you start throwing around slander claims, please look it up to understand what it really means. If you drop the 'tude' a couple notches, then other members may be more helpfull down the road when you do get the lathe going and want advice on repairs, etc. It's a small world out there.......

Just my opinion.

Dave

http://forums.azbilliards.com/showthread.php?t=173278

I think this is the lathe you have,Why dont you call or e-mail Todd (the maker of the lathe) He is usually good with any questions you might have

I think this is the lathe you have,Why dont you call or e-mail Todd (the maker of the lathe) He is usually good with any questions you might have

I have same headstock on a tip lathe I put together.The motor and controller cost about a hundred. I just had to make some brackets and a pulley for it.

Are you serious? Do you want to have an intelligent conversation with people or pick on how someone uses a figure of speech. Get a life. I was Explaining in a hurry what I was working with and what I was looking for. Isnt slandering frowned upon on here? - Especially from such a respected "cuemaker" as someone like yourself..

I'm done. You're on your own from here forward.

I certainly do appreciate an intelligent conversation but I don't see

that happening at this point in time.

Frankly, I think you have bigger problems than just a short cord.

Good Luck. I think you're going to need it.

PS - reread post #18. The advice contained therein should have been your

first move from the get-go.