Best I could do. It's stuck on with double sided tape. My friend says the cushion chunk is Championship MBS K66 from pooltables.com. Hopefully I'll get the chunk of K55 after this weekend. One of his buddies is getting new K55 cushions this weekend, but he lives near Lansing.You can post the result with your new piece of K66, it's always interesting! Photo!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Looking for some sub rail angle advice

- Thread starter MISteve

- Start date

This K66 is higher than the old one that was there before and it seems correct for the height of subrail that you have, in principle the K55 should reach 1 3/8'' very close, which would be too low, curious to see the K55, we will see what the great chief RKC will say about that, you're on the good way!Best I could do. It's stuck on with double sided tape. My friend says the cushion chunk is Championship MBS K66 from pooltables.com. Hopefully I'll get the chunk of K55 after this weekend. One of his buddies is getting new K55 cushions this weekend, but he lives near Lansing.

Since it somehow seems to be relevant to this thread......

My career progression is as follows: Machinist -> Mechanical Designer -> New Product Development Project Manager -> Pool Table Technician

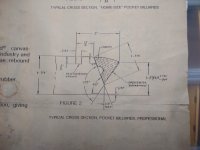

I have attached 2 images. The catalog photo is directly from Brunswick, regarding the proper mounting specifications of their Brunswick Superspeed cushions. Note that the sub-rail in the Brunswick catalog is actually 1 23/32".

The other image is one that I created, using Autodesk Inventor. This shows what a Brunswick Superspeed cushion looks like, when mounted to a 1 11/16" sub-rail. When we modify old Brunswick rails, to accommodate a modern K55 cushion, we knock the sub-rail thickness down to 1 11'16". This provides a straight and true surface to work with, which later ensures that the cushion is mounted along a precise guide, thereby ensuring a straight and accurate cushion nose height.

If your rail matches the measurements in the image that I created, as you have suggested earlier in this thread, the nose height of a K55 cushion should be pretty close to what is spec'd here..... If not, then the ONLY explanation is that your measurements are off. Based on your last photo, showing the K66 cushion mounted to the rail, which shows a nose height of 1 27/64", I would guess that the K55 cushion is going to measure somewhere close to 1 11/32". That's nowhere close to what it should be, with the measurements that you have provide.

All of that said, based on your photos, K66 is the correct cushion for your table, without modification of the rails.

My career progression is as follows: Machinist -> Mechanical Designer -> New Product Development Project Manager -> Pool Table Technician

I have attached 2 images. The catalog photo is directly from Brunswick, regarding the proper mounting specifications of their Brunswick Superspeed cushions. Note that the sub-rail in the Brunswick catalog is actually 1 23/32".

The other image is one that I created, using Autodesk Inventor. This shows what a Brunswick Superspeed cushion looks like, when mounted to a 1 11/16" sub-rail. When we modify old Brunswick rails, to accommodate a modern K55 cushion, we knock the sub-rail thickness down to 1 11'16". This provides a straight and true surface to work with, which later ensures that the cushion is mounted along a precise guide, thereby ensuring a straight and accurate cushion nose height.

If your rail matches the measurements in the image that I created, as you have suggested earlier in this thread, the nose height of a K55 cushion should be pretty close to what is spec'd here..... If not, then the ONLY explanation is that your measurements are off. Based on your last photo, showing the K66 cushion mounted to the rail, which shows a nose height of 1 27/64", I would guess that the K55 cushion is going to measure somewhere close to 1 11/32". That's nowhere close to what it should be, with the measurements that you have provide.

All of that said, based on your photos, K66 is the correct cushion for your table, without modification of the rails.

Attachments

i am glad there are people who understand those pictures and can make it happen....Since it somehow seems to be relevant to this thread......

My career progression is as follows: Machinist -> Mechanical Designer -> New Product Development Project Manager -> Pool Table Technician

I have attached 2 images. The catalog photo is directly from Brunswick, regarding the proper mounting specifications of their Brunswick Superspeed cushions. Note that the sub-rail in the Brunswick catalog is actually 1 23/32".

The other image is one that I created, using Autodesk Inventor. This shows what a Brunswick Superspeed cushion looks like, when mounted to a 1 11/16" sub-rail. When we modify old Brunswick rails, to accommodate a modern K55 cushion, we knock the sub-rail thickness down to 1 11'16". This provides a straight and true surface to work with, which later ensures that the cushion is mounted along a precise guide, thereby ensuring a straight and accurate cushion nose height.

If your rail matches the measurements in the image that I created, as you have suggested earlier in this thread, the nose height of a K55 cushion should be pretty close to what is spec'd here..... If not, then the ONLY explanation is that your measurements are off. Based on your last photo, showing the K66 cushion mounted to the rail, which shows a nose height of 1 27/64", I would guess that the K55 cushion is going to measure somewhere close to 1 11/32". That's nowhere close to what it should be, with the measurements that you have provide.

All of that said, based on your photos, K66 is the correct cushion for your table, without modification of the rails.

snookered_again

Well-known member

if the cushion is too low the ball will hop on return. you can shim the rail and see at what point that happens. Im not saying that the dimensions are not important, just that you can note if it is too low, that part becomes quite obvious.. the converse is that the ball is driven downward, thats a bit harder to see, and also not favorable..

as a comparison, if I set up an older non electronically controlled car's timing and it was an engine built of a bunch of different parts the manual may not apply, so Ill go up a hill listening for it pinking and adjust the distributor by way of small adjustments and trial and error.

it is of course hard to lower the cushion to test, shimming it a little higher, as a test, is easy. you might be able to add some stiff cardboard either between the rail and the slate or even on top of the slate just to bounce a ball and observe differences in action.. if the rail is at all loose it will mess up your bounce.

Fine measuring is all good and well but how it bounces is a further indication.. If you are recovering the rails I'd try one and mount it, that might be a good excercise , before you recover them all..

double sided tape is mickey mouse, if the cushion is loose or has stuff like that between it will kill the bounce. a slow moving ball wiill refuse to rebound much. that's a "dead rail"

as a comparison, if I set up an older non electronically controlled car's timing and it was an engine built of a bunch of different parts the manual may not apply, so Ill go up a hill listening for it pinking and adjust the distributor by way of small adjustments and trial and error.

it is of course hard to lower the cushion to test, shimming it a little higher, as a test, is easy. you might be able to add some stiff cardboard either between the rail and the slate or even on top of the slate just to bounce a ball and observe differences in action.. if the rail is at all loose it will mess up your bounce.

Fine measuring is all good and well but how it bounces is a further indication.. If you are recovering the rails I'd try one and mount it, that might be a good excercise , before you recover them all..

double sided tape is mickey mouse, if the cushion is loose or has stuff like that between it will kill the bounce. a slow moving ball wiill refuse to rebound much. that's a "dead rail"

I didn't read all of your novel, but I did catch the comment about double-sided tape....double sided tape is mickey mouse, if the cushion is loose or has stuff like that between it will kill the bounce. a slow moving ball wiill refuse to rebound much. that's a "dead rail"

He's simply using it for mock up. Nothing wrong with that

if the cushion is too low the ball will hop on return. you can shim the rail and see at what point that happens. Im not saying that the dimensions are not important, just that you can note if it is too low, that part becomes quite obvious.. the converse is that the ball is driven downward, thats a bit harder to see, and also not favorable..

as a comparison, if I set up an older non electronically controlled car's timing and it was an engine built of a bunch of different parts the manual may not apply, so Ill go up a hill listening for it pinking and adjust the distributor by way of small adjustments and trial and error.

it is of course hard to lower the cushion to test, shimming it a little higher, as a test, is easy. you might be able to add some stiff cardboard either between the rail and the slate or even on top of the slate just to bounce a ball and observe differences in action.. if the rail is at all loose it will mess up your bounce.

Fine measuring is all good and well but how it bounces is a further indication.. If you are recovering the rails I'd try one and mount it, that might be a good excercise , before you recover them all..

double sided tape is mickey mouse, if the cushion is loose or has stuff like that between it will kill the bounce. a slow moving ball wiill refuse to rebound much. that's a "dead rail"

@snookered_again has not yet learned to give the monarch notes to anythingI didn't read all of your novel, but I did catch the comment about double-sided tape....

He's simply using it for mock up. Nothing wrong with that

its too bad because he has good things to say

but i guess

CONCISE

is not in his DNA

just sayin

I don't know Goeff, without having the rails and cushions in my hands, it's hard to say what's what with fact. All I know for sure is, K66 cushions mounted on a GC rail with that 23.5 degree bevel is going to set the nose height at about 1 9/16" so those rails must have had K55 cushions to begin with.Since it somehow seems to be relevant to this thread......

My career progression is as follows: Machinist -> Mechanical Designer -> New Product Development Project Manager -> Pool Table Technician

I have attached 2 images. The catalog photo is directly from Brunswick, regarding the proper mounting specifications of their Brunswick Superspeed cushions. Note that the sub-rail in the Brunswick catalog is actually 1 23/32".

The other image is one that I created, using Autodesk Inventor. This shows what a Brunswick Superspeed cushion looks like, when mounted to a 1 11/16" sub-rail. When we modify old Brunswick rails, to accommodate a modern K55 cushion, we knock the sub-rail thickness down to 1 11'16". This provides a straight and true surface to work with, which later ensures that the cushion is mounted along a precise guide, thereby ensuring a straight and accurate cushion nose height.

If your rail matches the measurements in the image that I created, as you have suggested earlier in this thread, the nose height of a K55 cushion should be pretty close to what is spec'd here..... If not, then the ONLY explanation is that your measurements are off. Based on your last photo, showing the K66 cushion mounted to the rail, which shows a nose height of 1 27/64", I would guess that the K55 cushion is going to measure somewhere close to 1 11/32". That's nowhere close to what it should be, with the measurements that you have provide.

All of that said, based on your photos, K66 is the correct cushion for your table, without modification of the rails.