You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

motor question

- Thread starter Dave38

- Start date

VARIABLE SPEED SEWING MACHINE MOTOR motor on ebay 3/4 hr

http://stores.ebay.com/CuTex-Sewing-...p2047675.l2563

check out this tread New power for old Porpers

http://stores.ebay.com/CuTex-Sewing-...p2047675.l2563

check out this tread New power for old Porpers

Last edited:

Is anyone using a treadmill motor to run their lathe? I am thinking of picking one up for the deluxe so I can core with it. Are they really as strong as the ratings show? Most seem to be around the 2.5 hp range.

Thanks,

Dave

I use a 1/2 hp AC motor 1725 rpm to core on my deluxe....

The tread mill motor will definatly do it also. The controller senses a load and torques up the motor. I had one on a spinner for finishing.... it would rip your arm off if you got in the way..... I had a 2 1/2 hp motor from a proform tread mill. I got mine under FREE stuff on craigs list.....I removed the motor and controller board and took the rest to the dump. there are instructions for wiring the MC60 controller on the internet..................

Kim

I use a 1/2 hp AC motor 1725 rpm to core on my deluxe....

The tread mill motor will definatly do it also. The controller senses a load and torques up the motor. I had one on a spinner for finishing.... it would rip your arm off if you got in the way..... I had a 2 1/2 hp motor from a proform tread mill. I got mine under FREE stuff on craigs list.....I removed the motor and controller board and took the rest to the dump. there are instructions for wiring the MC60 controller on the internet..................

Kim

when I bought my deluxe...used... it already had a Penn State motor on it. It works fine, but coring is a different animal. I don't like changing things back and forth, from a AC to a DC motor over and over, would rather have one motor that can do it all. I want to do a full 30" core, and the only lathe I have that can do it is the deluxe, but it needs a boost in the motor dept. for sure. My Atlas lathe

can only do about a 17" core

It sounds like a 2.5 hp motor will be great....but the Penn State has a rating of 1/2 hp and I beg to differ on that. Hence my question, Can one believe the specs?

The sewing machine motor is a good idea, but looking for more Horse Power than they can provide.

Dave

Hi David,

I use one of the treadmill motors on my finish-lathe, DC 2-1/2hp variable spd.

I got it about 15-20 yrs ago, new with the controller for about $45. Overstock.

Overkill also. Tremendous torque. Way more than what I need for a finish-lathe

but for the price and the convenience of variable spd. I thought, what the hey.

It's been totally trouble free in all this time but it does have one drawback.

They are NOT reversible nor can they be made to reverse.

In it's intended application, it's not necessary. Who walks backwards on a treadmill?

FWIW, sewing machine mtrs aren't reversible either.

I've been dabbling with Dayton DC gearmotors lately for different applications

and am somewhat familiar with the MC-series of controllers, MC-20 through MC-68.

I'm not suggesting a gearmotor for your application, just saying that

the MC-60 is a good controller and they are common/plentiful.

Is the treadmill motor powerful enough?

Let's put it this way. I see you twisting your lathe before you stall the motor.

KJ

I use one of the treadmill motors on my finish-lathe, DC 2-1/2hp variable spd.

I got it about 15-20 yrs ago, new with the controller for about $45. Overstock.

Overkill also. Tremendous torque. Way more than what I need for a finish-lathe

but for the price and the convenience of variable spd. I thought, what the hey.

It's been totally trouble free in all this time but it does have one drawback.

They are NOT reversible nor can they be made to reverse.

In it's intended application, it's not necessary. Who walks backwards on a treadmill?

FWIW, sewing machine mtrs aren't reversible either.

I've been dabbling with Dayton DC gearmotors lately for different applications

and am somewhat familiar with the MC-series of controllers, MC-20 through MC-68.

I'm not suggesting a gearmotor for your application, just saying that

the MC-60 is a good controller and they are common/plentiful.

Is the treadmill motor powerful enough?

Let's put it this way. I see you twisting your lathe before you stall the motor.

KJ

Hi David,

I use one of the treadmill motors on my finish-lathe, DC 2-1/2hp variable spd.

I got it about 15-20 yrs ago, new with the controller for about $45. Overstock.

Overkill also. Tremendous torque. Way more than what I need for a finish-lathe

but for the price and the convenience of variable spd. I thought, what the hey.

It's been totally trouble free in all this time but it does have one drawback.

They are NOT reversible nor can they be made to reverse.

In it's intended application, it's not necessary. Who walks backwards on a treadmill?

FWIW, sewing machine mtrs aren't reversible either.

I've been dabbling with Dayton DC gearmotors lately for different applications

and am somewhat familiar with the MC-series of controllers, MC-20 through MC-68.

I'm not suggesting a gearmotor for your application, just saying that

the MC-60 is a good controller and they are common/plentiful.

Is the treadmill motor powerful enough?

Let's put it this way. I see you twisting your lathe before you stall the motor.

KJ

Not to argue but every dc treadmill motor I have used is reversible. Just install a 6 pole double throw reversing switch between the controller and motor.

I'm not interested in arguing either.

A quick trip to eBay will confirm what I'm saying.

The motors are labeled with their direction of rotation.

Some are labeled CW & some are labeled CCW.

Why would they label them as such if it didn't make any difference?

You state that you've never seen one that wasn't reversible.

I'm stating that I've never seen one that IS reversible.

If you'd care to show an example, I'd be interested to see it.

KJ

A quick trip to eBay will confirm what I'm saying.

The motors are labeled with their direction of rotation.

Some are labeled CW & some are labeled CCW.

Why would they label them as such if it didn't make any difference?

You state that you've never seen one that wasn't reversible.

I'm stating that I've never seen one that IS reversible.

If you'd care to show an example, I'd be interested to see it.

KJ

KJ, there as always may be some exceptions but any treadmill motor I have used is reversible. The reason they put rotation on a lot of them is because of the pulley being threaded onto the shaft. Run it backwards and the pulley would unscrew. Most guys in our crazy world would not use that pulley anyways and adapt another to the shaft. You could also "pin" the original pulley to the shaft if desired.

MC boards are good and if your looking for braking, option of speed or torque settings in both forward and reverse then check out the KBMG 212D boards. If you look around you can find some deals on them. I bought 3 almost brand new with covers for the retail price of one.

MC boards are good and if your looking for braking, option of speed or torque settings in both forward and reverse then check out the KBMG 212D boards. If you look around you can find some deals on them. I bought 3 almost brand new with covers for the retail price of one.

I'm not interested in arguing either.

A quick trip to eBay will confirm what I'm saying.

The motors are labeled with their direction of rotation.

Some are labeled CW & some are labeled CCW.

Why would they label them as such if it didn't make any difference?

You state that you've never seen one that wasn't reversible.

I'm stating that I've never seen one that IS reversible.

If you'd care to show an example, I'd be interested to see it.

KJ

I have read that the brushes are angled for a specific rotation on some DC motors...all the treadmill motors I have seen are labeled for one direction. ...

Kim

when I bought my deluxe...used... it already had a Penn State motor on it. It works fine, but coring is a different animal. I don't like changing things back and forth, from a AC to a DC motor over and over, would rather have one motor that can do it all. I want to do a full 30" core, and the only lathe I have that can do it is the deluxe, but it needs a boost in the motor dept. for sure. My Atlas lathe

can only do about a 17" core

It sounds like a 2.5 hp motor will be great....but the Penn State has a rating of 1/2 hp and I beg to differ on that. Hence my question, Can one believe the specs?

The sewing machine motor is a good idea, but looking for more Horse Power than they can provide.

Dave

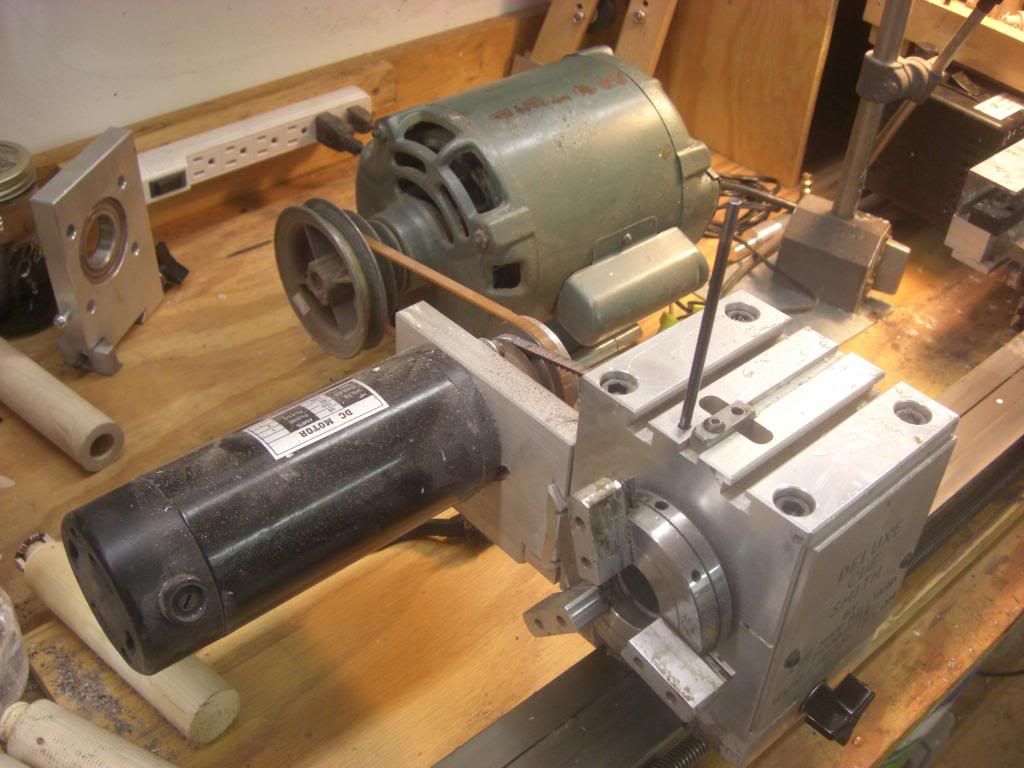

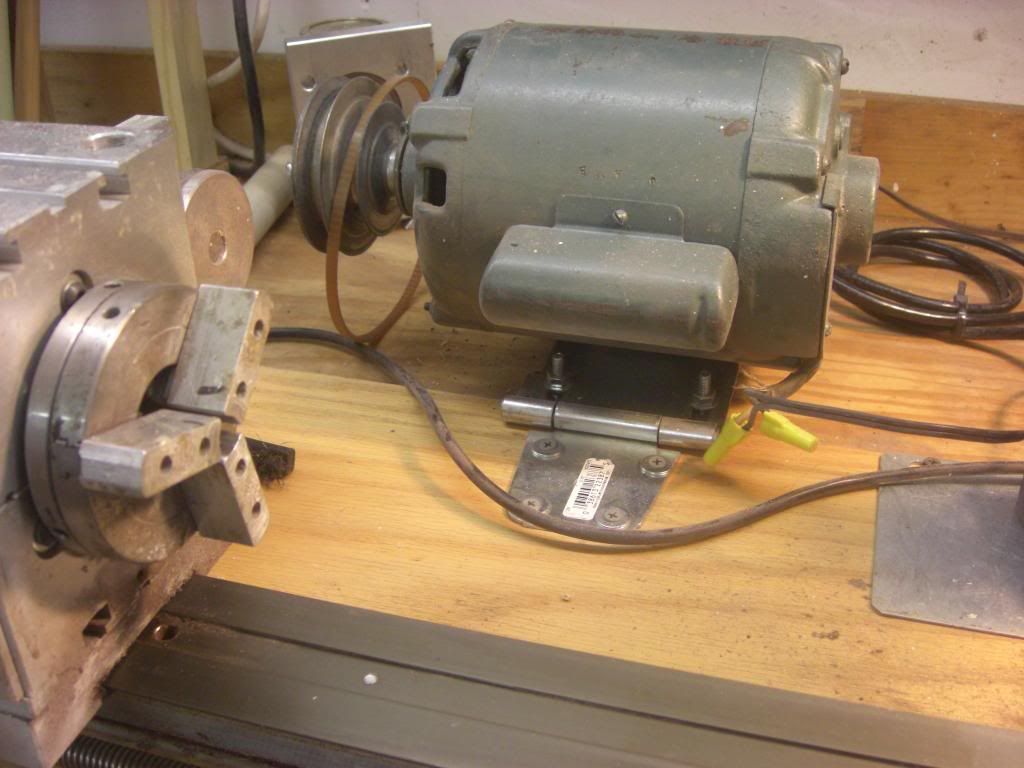

The Pennstate motor is great for the deluxe. Check out how to add an AC motor for coring.

The AC motor is mounted on a hinge. Just slide the head stock back until the motor pulleys line up and slip a belt on it.............. works great and takes about 5 seconds to set up............ be sure to unplug the DC motor when you do this......... if it is plugged in, you will get motor drag because PM DC motors are generators when you drive them........

Kim

Kim,

That's a pretty slick idea. One thing though, it looks like you unplug your DC motor when you connect the AC motor and that's a good thing. In fact, you should also disconnect it from the speed controller. When you spin a DC motor, it generates DC voltage and current. The speed controller may not be configured to block that voltage and you could burn one up. That's why the treadmill motors and other DC motors are often advertised as "wind turbine" motors.

Not sure if everyone was aware of that.

Gary

That's a pretty slick idea. One thing though, it looks like you unplug your DC motor when you connect the AC motor and that's a good thing. In fact, you should also disconnect it from the speed controller. When you spin a DC motor, it generates DC voltage and current. The speed controller may not be configured to block that voltage and you could burn one up. That's why the treadmill motors and other DC motors are often advertised as "wind turbine" motors.

Not sure if everyone was aware of that.

Gary

Kim,

That's a pretty slick idea. One thing though, it looks like you unplug your DC motor when you connect the AC motor and that's a good thing. In fact, you should also disconnect it from the speed controller. When you spin a DC motor, it generates DC voltage and current. The speed controller may not be configured to block that voltage and you could burn one up. That's why the treadmill motors and other DC motors are often advertised as "wind turbine" motors.

Not sure if everyone was aware of that.

Gary

Yes I always unplug the DC motor when using the AC motor. You can tell if the DC motor is generating by just trying to spin it backwards by hand when it is off (and plugged in). It is harder to turn backwards because it is generating.

Kim

Back to Dave's question, I have an Enco 3-in-1 lathe that came with a reversible AC motor and a boogered up switch. The switch wiring was too complicated for me, so I replaced that motor with a Pacific Scientific 2.5HP DC motor out of a free treadmill and used the MC-60 speed controller that also came out of the treadmill to control it. I simply put a DP/DT switch in between the DC output side of the controller and the motor and it runs forward and reverse.

The motor has more than enough torque to core, but it's so heavy I'm not sure it would be a good fit for Kim's setup. For a permanent setup, sure.

My 2 cents,

Gary

The motor has more than enough torque to core, but it's so heavy I'm not sure it would be a good fit for Kim's setup. For a permanent setup, sure.

My 2 cents,

Gary

Hello, I just want to back up KJ on this one. In his specific case, I actually tried to get his motor to reverse, and it absolutely would not. I am an industrial electrician, so I know how to reverse a DC motor, all you need to do is to reverse the polarity of either the rotor leads OR the stator leads, but not both. On KJ's motor, I reversed one, and it still spun the same direction, then I put those leads back the original way and reversed the other and it still spun the original way. I was perplexed enough to ask around where I work of the other electricians and even the electrical technicians. I was informed that the motor probably had shunt field windings installed internally that would allow it to rotate in one direction only. Now I am not saying that all DC treadmill motors are like this, but the one he has on his finishing lathe is most definitely NOT reversible. Hope this clears up any confusion. Thanks for listening.

Jim Notestine

Jim Notestine

Jim,

You bring up a good point. There are two kinds of DC motors - PM (Permanent Magnet) and Field Wound motors where coils of wire surround the armature, just like in an AC motor.

I found this explanation when doing a little research:

"To reverse rotation on the DC motor, one has to switch the relative polarity between the armature and field. So, if it is a two terminal motor with the field connected to the brush internally, it will rotate the same direction, regardless of the polarity (+ or -) connected to the two terminals. Reversible motors will have four terminals, two for the armature (A1 & A2) and two for the field (S1 & S2). The field to armature connection is made external to the motor. So, connecting A1 to S1, and power to the other two, will rotate one direction. Connecting A1 to S2 and power to the remaining two will cause opposite rotation.

A similar thing with shunt or SepEx, except field and armature are not in series. PM motors are easy because the field (permanent magnet) always is the same polarity (N, S), so one just has to reverse the electrical polarity on the two terminals, which are connected to the brushes inside and then to the armature thru the comm."

Source: http://www.diyelectriccar.com/forums/showthread.php/makes-dc-motor-reversible-25497.html

I wasn't doubting KJ, just giving an example of what I did - and yes, my motor is a PM motor.

Good discussion:thumbup:

Gary

You bring up a good point. There are two kinds of DC motors - PM (Permanent Magnet) and Field Wound motors where coils of wire surround the armature, just like in an AC motor.

I found this explanation when doing a little research:

"To reverse rotation on the DC motor, one has to switch the relative polarity between the armature and field. So, if it is a two terminal motor with the field connected to the brush internally, it will rotate the same direction, regardless of the polarity (+ or -) connected to the two terminals. Reversible motors will have four terminals, two for the armature (A1 & A2) and two for the field (S1 & S2). The field to armature connection is made external to the motor. So, connecting A1 to S1, and power to the other two, will rotate one direction. Connecting A1 to S2 and power to the remaining two will cause opposite rotation.

A similar thing with shunt or SepEx, except field and armature are not in series. PM motors are easy because the field (permanent magnet) always is the same polarity (N, S), so one just has to reverse the electrical polarity on the two terminals, which are connected to the brushes inside and then to the armature thru the comm."

Source: http://www.diyelectriccar.com/forums/showthread.php/makes-dc-motor-reversible-25497.html

I wasn't doubting KJ, just giving an example of what I did - and yes, my motor is a PM motor.

Good discussion:thumbup:

Gary

Back to Dave's question, I have an Enco 3-in-1 lathe that came with a reversible AC motor and a boogered up switch. The switch wiring was too complicated for me, so I replaced that motor with a Pacific Scientific 2.5HP DC motor out of a free treadmill and used the MC-60 speed controller that also came out of the treadmill to control it. I simply put a DP/DT switch in between the DC output side of the controller and the motor and it runs forward and reverse.

The motor has more than enough torque to core, but it's so heavy I'm not sure it would be a good fit for Kim's setup. For a permanent setup, sure.

My 2 cents,

Gary

Yea... you are right ... those treadmill motors weigh a ton......I still have it on the shelf but the AC motor is better for me.. I can vary the speed of coring by putting my belt on a different size pulley on my AC motor that I stole off an old shopsmith. That AC motor is NOT reversible, that is why it is mounted the way it is.

Kim

I have found almost all DC motor ratings to be a little high. The HP rating is only close to good for the very top speed and when using the very highest dollar electronic controllers. So with that said, even if the 2.5HP rating is a little high, it should still be way more than enough.

American motor manufacturers usually rate in actual HP and not on what some call Peak HP. I am guessing most Asian manufacuturers of motors might be using the Peak HP method for the motor rating which is less than the actual Continuous HP rating.

American motor manufacturers usually rate in actual HP and not on what some call Peak HP. I am guessing most Asian manufacuturers of motors might be using the Peak HP method for the motor rating which is less than the actual Continuous HP rating.

Last edited:

I like the idea of Kim's hookup and looked to do it, but I have almost no extra space behind the Penn motor to setup an AC motor unfortunately. I have drawer units and stuff right there that can't be moved easily. Too bad because I have like 2-3 unsed AC motors that would be great for it. I thank everyone for their responses and ideas. It's good to know that those motors are that strong. I have a couple friends keeping an eye out for treadmills that people don't want, hopefully I can get my hands on one or two.

Thanks,

Dave

Thanks,

Dave

I like the idea of Kim's hookup and looked to do it, but I have almost no extra space behind the Penn motor to setup an AC motor unfortunately. I have drawer units and stuff right there that can't be moved easily. Too bad because I have like 2-3 unsed AC motors that would be great for it. I thank everyone for their responses and ideas. It's good to know that those motors are that strong. I have a couple friends keeping an eye out for treadmills that people don't want, hopefully I can get my hands on one or two.

Thanks,

Dave

Can you mount an ac motor under your bench?

Cut a hole in the bench and feed the drive belt to the motor underneath the lathe...