We sold the first five and are now making eight more. The Mechanical Ball Cleaner and Polisher is now listed on Ebay

http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&rd=1&item=330255152875&ssPageName=STRK:MESE:IT&ih=014

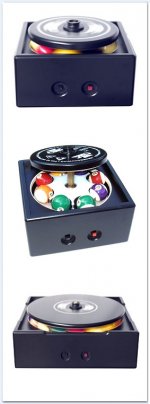

If you would like to see how well it works, look at the photo. The balls shown are about two years old and were polished in less than five minutes.

http://cgi.ebay.com/ws/eBayISAPI.dll?ViewItem&rd=1&item=330255152875&ssPageName=STRK:MESE:IT&ih=014

If you would like to see how well it works, look at the photo. The balls shown are about two years old and were polished in less than five minutes.

Last edited: