And a few more!

Not a lot of pictures for the 4+ hours I was turning this, but taper passes on a full length butt are not the most exiting thing to see...

Anyway, it is 0.050" oversize now, and sealed with Cyano to keep it clean and stable as I get ready to do some inlay work...

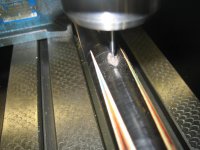

First photo is verifying my taper is where I want it

Second is a sample of the hours of cutting I did last night... Note that tool was not used for all the turning; just the 'roughing' as it has too much radius on it ans chatters too much. I went back to my small radius cutter later.

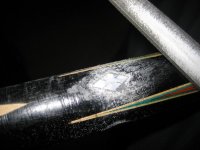

Third is a close up of the ring work in the butt. Note chatter which made me change the tool. I should have just stuck with the one I normally use...

Fourth is the cue as it is now- with a coating of Cyano to keep every thing clean and stable. That will be cut off when I do my final taper after inlays.

Not a lot of pictures for the 4+ hours I was turning this, but taper passes on a full length butt are not the most exiting thing to see...

Anyway, it is 0.050" oversize now, and sealed with Cyano to keep it clean and stable as I get ready to do some inlay work...

First photo is verifying my taper is where I want it

Second is a sample of the hours of cutting I did last night... Note that tool was not used for all the turning; just the 'roughing' as it has too much radius on it ans chatters too much. I went back to my small radius cutter later.

Third is a close up of the ring work in the butt. Note chatter which made me change the tool. I should have just stuck with the one I normally use...

Fourth is the cue as it is now- with a coating of Cyano to keep every thing clean and stable. That will be cut off when I do my final taper after inlays.