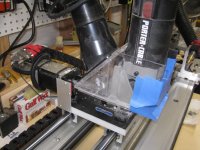

Saw three e pieces of 1/2 plexiglass.

Epoxy 'em and then put one screw through each plate.

Third piece gets hole-sawed to make room for turning wood.

Card board covers the router from blowing air in that area ( somewhat ).

There's a gap between that custom made cardboard so the router can still fart hot air.:grin:

5-inch tube/spacers hold the fromt and top.

If you have a better idea, let's hear it.

It's not patented of course.

Be safe.

Epoxy 'em and then put one screw through each plate.

Third piece gets hole-sawed to make room for turning wood.

Card board covers the router from blowing air in that area ( somewhat ).

There's a gap between that custom made cardboard so the router can still fart hot air.:grin:

5-inch tube/spacers hold the fromt and top.

If you have a better idea, let's hear it.

It's not patented of course.

Be safe.

Attachments

Last edited: