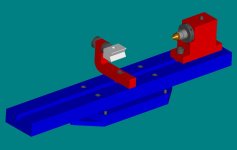

Beautiful design and workmanship

Pete,

I think your rig is the cats ass. Are you selling them and if so, how much do you want?

I have a fixture now, but I like your utility of adjustment and quality. Let me know if you are selling one and the lead time doesn't matter.

A question I have is about the steady rest fixture with the V block. Is it critical to use this device when cutting point grooves in a 13" to 14" tapered forearm blank? It is obviously to fight deflection. Please comment on this feature and let me know your thoughts and experience concerning this device.

I have a 90 degree cutter in a 1/3 hp Hitachi router with a 1/2 inch shank. I have a frame that holds the router square and plumb. My 5c collet indexer is mounted on a fixture with a tailstock. I am getting a very good product without the steady rest. The reason I would want a unit like yours is because I will be buying a mill in the near future and want a heavy duty unit like yours to do the best job that I can do.

Very truly yours,

Rick Geschrey

cell phone # 847 641-0276