Hey guys.... For those that use the sanding mandrels for guides, are you gluing the pin in the butt before you sand down to size? Any info you can give to help?... I am getting my mandrels today and ready to do my first sanding using the mandrels. Thanks

Sanding Mandrel use

- Thread starter captainjko

- Start date

How can you sand the cue down without the pin installed?

1. Final turn.

2. Install pin.

3. Sand flush to prefinish size mandrel. (if you are getting two sets)

4. Apply finish.

5. Sand and polish flush to post finish size mandrel.

There are some little nuances and details to carbide mandrel use. You will have to figure out some details that work for you, based on your finish specs, method of application etc.

1. Final turn.

2. Install pin.

3. Sand flush to prefinish size mandrel. (if you are getting two sets)

4. Apply finish.

5. Sand and polish flush to post finish size mandrel.

There are some little nuances and details to carbide mandrel use. You will have to figure out some details that work for you, based on your finish specs, method of application etc.

I do it as:

1. Final cut to .008" under size

2. Install joint pin

3. Face joint

4. Screw on arbor

5. Lightly sand for finish prep

6. Apply finish

7. Sand/polish finish

8. Remove arbor & lightly bevel edge of finish so it won't chip

I use only one set of arbors. Lots of guys use two. Personal preference as everybody creates their own methods/habits. Most important is to make everything routine so you attain a level of consistency. IMO, sanding arbors are the best thing to happen to cue making since God invented maple.

1. Final cut to .008" under size

2. Install joint pin

3. Face joint

4. Screw on arbor

5. Lightly sand for finish prep

6. Apply finish

7. Sand/polish finish

8. Remove arbor & lightly bevel edge of finish so it won't chip

I use only one set of arbors. Lots of guys use two. Personal preference as everybody creates their own methods/habits. Most important is to make everything routine so you attain a level of consistency. IMO, sanding arbors are the best thing to happen to cue making since God invented maple.

1. Final cut to .842"

2. Install joint pin

3. Face joint

4. Screw on small arbor .800

5. Lightly sand for finish prep

6. Apply finish

7. face joint

8. screw on sanding mandrel .850

9. wet sand to match joint to mandrel

10.screw on small mandrel .800

11. wet Sand/polish finish

Kim

2. Install joint pin

3. Face joint

4. Screw on small arbor .800

5. Lightly sand for finish prep

6. Apply finish

7. face joint

8. screw on sanding mandrel .850

9. wet sand to match joint to mandrel

10.screw on small mandrel .800

11. wet Sand/polish finish

Kim

IF the butt has no joint screw, how do you mate it with the mandrel????

Word of advice, sand very little or nothing at all off the butt's joint collar before applying the finish. If that joint screw needs replacing later on, it will be a nightmare to replace it.

Leave the shafts .002" oversized of the butt and sand those down to match.

The lathe does not have to spin to mate when sanding shafts down a little to mate with the butt . But, do not use a sanding block.

Word of advice, sand very little or nothing at all off the butt's joint collar before applying the finish. If that joint screw needs replacing later on, it will be a nightmare to replace it.

Leave the shafts .002" oversized of the butt and sand those down to match.

The lathe does not have to spin to mate when sanding shafts down a little to mate with the butt . But, do not use a sanding block.

Thanks for the info guys... I am just starting out putting a cue together..... I really appreciate it..

Thanks for the info guys... I am just starting out putting a cue together..... I really appreciate it..

If you paid a high price for a quality set of carbide mandrels, in my opinion you did yourself a favor just starting out. The $350-$400 for a quality set is expensive, but when you consider they will outlast you and will be used for every single cue you ever build (with that pin type of course) they become quite economical.

Thanks for the input guys..... I think it turned out pretty good.... Going to put an epoxy finish on it next week..... Do you guys coat the whole shaft? Or just the first few inches and feather it in?

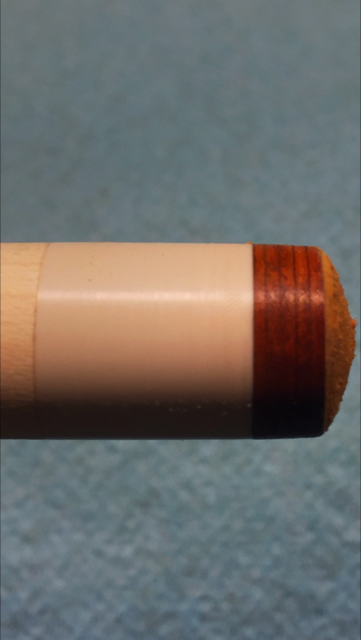

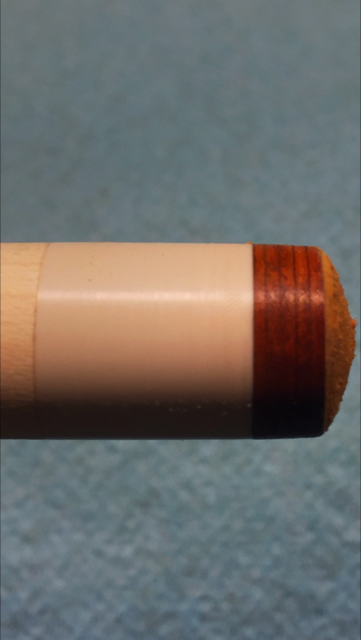

Purpleheart / maple ..... Tomahawk ferrule, Dennis Searing med. tip.

Made this extension too.......

Tomahawk ferrule and Searing medium tip..

Purpleheart / maple ..... Tomahawk ferrule, Dennis Searing med. tip.

Made this extension too.......

Tomahawk ferrule and Searing medium tip..