I would like to know what other cuemakers think about screw on ferrules verses the sleeve type. Once the epoxy sets is there any meaningful difference in "feel", "hit", or strength?

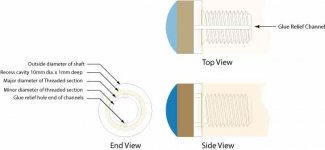

What about the ferrule tenon size?

Does that make any real difference or does the tenon and ferrule act as one solid part once the eopxy has set.

What about the ferrule tenon size?

Does that make any real difference or does the tenon and ferrule act as one solid part once the eopxy has set.