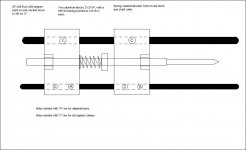

tail stock

Sheldon said:

I've got a stiff enough spring that the other end needs nothing more than a dead center. Much lighter, and I would have to rig up some kind of spur to keep the wood from slipping.

Hi Sheldon,and others who maybe interested,

been reading along about shaft machines. Some interesting post.

I do a little differant for the tail stock pressure. My drive is 60 deg. and has 6 sides machined on the point. This will not allow the shafts or butts to slip. Tail stock pressure is only about 6-lbs, at most. No need to have much tail stock pressure. Very little pressure will work just fine. All you need is just enough pressure to hold the part in between the centers. When turn cutting [ profiing] it's best to have as little end pressure as possible, so you don't distort [ bow them with pressure],in a relaxed state, just as they are when they are completed.Why do something that's not nessesary, or may cause a problem down line?

No need to stress the wood. With added tail stock pressure, your taking a chance on bowing the wood, [during the cutting process], meaning it's not in it's natural relaxed position.

Not trying to fuss with anyone, just relaying on how it's done by me. Worked for me for the last 30 plus years.

Helping out I don't mind at all, have been doing it for years. This is the main reason I got this topic started on AZ.

I had a private e-mail asking why I don't I show how my stuff works? Well guys, designing and building machines, selling them, feeds us. I give a lot of free help. But I must draw the line so to speak, in some cases, when it affects my income. I surly hope you understand. Please ask, and if I can, no problem, guys. If I can help you folks, I will.

blud