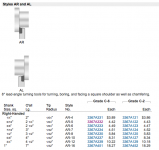

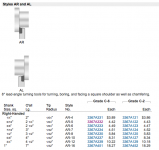

Below are the bits I have used for both metalworking and cue repairs. (From the Mcmaster Carr catalog). These are called carbide brazed. They are hard carbide onto a soft steel shank. A right hand bit is what you want. It means it cuts from right to left. I forget on your lathe if the toolholder uses a 3/8" bit or a smaller one. I have a Hightower, but put a quick change toolpost on it, that works up to 3/8". C-6 is harder than C-2. It probably won't make any difference with our appicaltin, but I normally buy the C-6.

You can also go the insert tooling route. However, that is much more expensive. I have used the same carbide brazed tool for several years. You just keep resharpening it. I also like to have two tools set up. One for the heavy cuts, and one I keep razor sharp once I'm on the last .005 or .010 (on the diameter).

Turing talk is diameter usually, not radius. You're lathe's hand wheel might be calibrated on the radius, but most metal working lathes are calibrated to the diameter.

When I worked in a metal tool room, I think one of these bits lasted me a whole year. I think I finally dropped it and it fractured. You will get a lot of mileage out of these.

If you go the carbide route, you will need a small diamond hone to touch up its edge. Do this right before the finish cut. Get the 250 and 400 grit of these. Get the $8 ones letter E. These will allow you to touch up the edge, and also polish it so you can take that really smooth cut.

http://www.mcmaster.com/#diamond-hones/=qbs1aw

If you want to alter the angle of the carbide (or HSS tooling), you need a grinder. If you have a bench grinder, change out one of its wheels to a wheel that will grind carbide. Then you can change the angles of the tool if you so desire. But when finished grinding, if you use the diamond hones (for either the carbide or HSS) to touch up the edge, you will have a much nicer finish on your parts.

In a rough sense, the more acute you make your tool angles, the sharper the tool will be. But it will also have less "meat" behind it, and the edge is weaker. Most of the info you will find about tool edge angles will be for metalworking. Where if you make the angle too acute, the tool won't last long. But in our application, you can get away with slightly sharper angles.

When you set up your tool bit, it should be set up so that you can turn and face without repositioning it. So in other words, you angle it so it splits the difference.

If you order from them, or MSC, (same type of place), they will start sending you little catalogs of metalworking stuff. Flip through every page, and just seeing the products you will learn a lot.