Just wondering if anyone knows where I can get a tool post holder for a Cue Smith Mid Size lathe that will hold a dial indicator. My DI has a diameter of .374 inches at the upper stem. This is just slightly too big for the tool post holder that came with the lathe. Any help is greatly appreciated. Thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool post holder for a dial indicator

- Thread starter Tom1234

- Start date

Tom, do you have a 3D printer? There's several designs on GrabCad and Thingiverse for such a holder. Or you can buy one already printed here:

JC

Coos Cues

Those are pretty slick but I believe he's trying to indicate his work, not his cross slide.Tom, do you have a 3D printer? There's several designs on GrabCad and Thingiverse for such a holder. Or you can buy one already printed here:

Recently purchased the basic mid-size solely just to do my own tips (purchased the larger machine with the ability to do more in the future if I decide to….or no longer like my money....)

Even wearing readers, my eyes aren’t good enough to read a small dial indicator.

I’m sure I’m not the first guy to do this – but an easy and economical way….

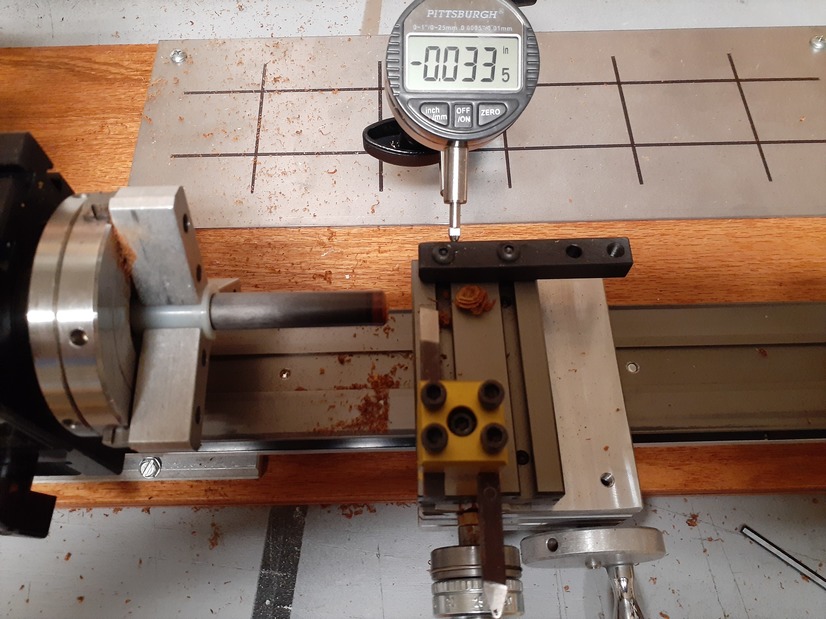

I just mounted 6”x18”x1/8” sheet steel (about $10 – any box store) behind the bed to hold a mag base wherever it needs to be.

Borrowed the indexing bar from the headstock and mounted it on the cross feed. Its 3-1/4” in length, tinkered with it until it ran out about a thousandth. Works well. (Obviously will have to do something different if I ever want a taper bar, use the spindle bore, etc. – but suits my purposes for now.)

(Just need to search the local pawn shops for a quality digital dial indicator – new starretts are pretty pricey….lol)

Even wearing readers, my eyes aren’t good enough to read a small dial indicator.

I’m sure I’m not the first guy to do this – but an easy and economical way….

I just mounted 6”x18”x1/8” sheet steel (about $10 – any box store) behind the bed to hold a mag base wherever it needs to be.

Borrowed the indexing bar from the headstock and mounted it on the cross feed. Its 3-1/4” in length, tinkered with it until it ran out about a thousandth. Works well. (Obviously will have to do something different if I ever want a taper bar, use the spindle bore, etc. – but suits my purposes for now.)

(Just need to search the local pawn shops for a quality digital dial indicator – new starretts are pretty pricey….lol)

I make 2 different style indicator mounts for the cuesmith / taig style lathes. One mounts to the dovetail and the other is for the cross feed . You can see them and order from here if interested . Www.actionbilliardsupply.com. Not trying to plug my site but I have been selling them on Facebook for a while and just added them to a website that I own to make ordering and tracking orders and shipping easier

sometimes simple is good...and cheap too! I suggest Harbor Freight for Dial indicators....accurate and cheap.....if it dies you can buy 3-4 of them for the cost of 1 starrett or big time name brand......we build cues, not the space shuttle...lolRecently purchased the basic mid-size solely just to do my own tips (purchased the larger machine with the ability to do more in the future if I decide to….or no longer like my money....)

Even wearing readers, my eyes aren’t good enough to read a small dial indicator.

I’m sure I’m not the first guy to do this – but an easy and economical way….

I just mounted 6”x18”x1/8” sheet steel (about $10 – any box store) behind the bed to hold a mag base wherever it needs to be.

Borrowed the indexing bar from the headstock and mounted it on the cross feed. Its 3-1/4” in length, tinkered with it until it ran out about a thousandth. Works well. (Obviously will have to do something different if I ever want a taper bar, use the spindle bore, etc. – but suits my purposes for now.)

(Just need to search the local pawn shops for a quality digital dial indicator – new starretts are pretty pricey….lol)

View attachment 598651

JC

Coos Cues

I received an E mail yesterday and here is one line I would like to quote from it.sometimes simple is good...and cheap too! I suggest Harbor Freight for Dial indicators....accurate and cheap.....if it dies you can buy 3-4 of them for the cost of 1 starrett or big time name brand......we build cues, not the space shuttle...lol

"I am a retired NASA Systems Engineer and I worked on sending rovers to Mars over the last 32 years. Of all my experiences, however, what I have found most challenging and interesting is trying to build cues."

Just saying..........

we build cues, not the space shuttle

In some ways there isn't much difference in the mind game of the two."I am a retired NASA Systems Engineer and I worked on sending rovers to Mars over the last 32 years. Of all my experiences, however, what I have found most challenging and interesting is trying to build cues."

Our work is .0005 - .001 trying hold a tolerance. Aero space work generally around .0002 is a large number.

The end game is the still the same except there aren't any pool tables on the moon or Mars.

I'm still amazed at the number of well known brand name cues that pass thru that won't stay straight (aren't straight) that are not very old at all and every excuse is given why this has happened except for the construction methods used.

IMO the challenge is real to assembling multiple pieces of different types of woods together and keeping them straight for long and extended periods of time in multiple conditions and not blaming humidity or other outside forces. (not including abuse which we can't control)

I'm not talking about changing tips or ferrules or putting a new wrap on and cleaning the shafts which I've seen some simple jobs as such that would make a healthy person feel sick to their stomach.

Don't be afraid to use your brain and think outside the box. If the results keep showing up in a negative light, it might be time to try something new.

I'm sure they may have to do that occasionally when sending a projectile into space.