You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Your thought on radially laminated butts?

- Thread starter fish2

- Start date

xX-Wizard-Xx

Well-known member

its another thing to attract customers

like butterfly cuesits another thing to attract customers

xX-Wizard-Xx

Well-known member

yup ....like butterfly cues

I think you should stop and consider why Predator chooses to do it this way. I'm not saying that radially laminating a core isn't a good thing, especially if you can't source or take the time to cure wood properly. But all the marketing aside, this has to do with the bottom line, plain and simple.

Good if it's cut from the same board.

But, no way to add weight in the middle.

You end up adding too much weight on top and bottom to get to 15 oz.

But, no way to add weight in the middle.

You end up adding too much weight on top and bottom to get to 15 oz.

IMO, a 1 3/8 laminated blank will have the most consistant hit and won't warp.

I build my cues on a 3/4" laminated 30" dowel. The difference in the hit only varies and 5 to 10 percent depending on the combo woods I use.

I took a 2 trace oscilloscope and put a 440 hertz concert A tuning frequency thru 8 different blanks from my frequency generator thru the cue and monitored the back end with a Barcus Berry pickup I borrowed from my Bass Fiddle. All blanks were tested without the pins installed.

The pattern between a maple cue exterior woods and one done with Ebony shows amplitude and frequency patterns that have a very similar profile. These two woods were the fartherest pattern difference but only about 10%. The other combos were are less.

End results from my test experiments is tha cues built on a core play very similar concern feedback.

I also tested some Ajoint cues with different combos and they show no similar pattern. Scrambled eggs. So they all played and felt very different.

All testing was done in 2007 and this was the reason I went to full coring on a 3/4" laminated maple dowel.

I core with gorilla poly glue which also produces a quieter hit. When i cored with West System it had more of a ping. Conversely if you like a loud cue with a ping my cues are not for you. My friend Wendell Weir advised me when I started building cues that he liked maple cues because they were quiet and he felt the hit right up his arm with his milk the cow

Stroke.

No way is right or wrong, just different. The cue maker has many choices.

I build my cues on a 3/4" laminated 30" dowel. The difference in the hit only varies and 5 to 10 percent depending on the combo woods I use.

I took a 2 trace oscilloscope and put a 440 hertz concert A tuning frequency thru 8 different blanks from my frequency generator thru the cue and monitored the back end with a Barcus Berry pickup I borrowed from my Bass Fiddle. All blanks were tested without the pins installed.

The pattern between a maple cue exterior woods and one done with Ebony shows amplitude and frequency patterns that have a very similar profile. These two woods were the fartherest pattern difference but only about 10%. The other combos were are less.

End results from my test experiments is tha cues built on a core play very similar concern feedback.

I also tested some Ajoint cues with different combos and they show no similar pattern. Scrambled eggs. So they all played and felt very different.

All testing was done in 2007 and this was the reason I went to full coring on a 3/4" laminated maple dowel.

I core with gorilla poly glue which also produces a quieter hit. When i cored with West System it had more of a ping. Conversely if you like a loud cue with a ping my cues are not for you. My friend Wendell Weir advised me when I started building cues that he liked maple cues because they were quiet and he felt the hit right up his arm with his milk the cow

Stroke.

No way is right or wrong, just different. The cue maker has many choices.

Last edited:

IMO, a 1 3/8 laminated blank will have the most consistant hit and won't warp.

I build my cues on a 3/4" laminated 30" dowel. The difference in the hit only varies and 5 to 10 percent depending on the combo woods I use.

I took a 2 trace oscilloscope and put a 440 hertz concert A tuning frequency thru 8 different blanks from my frequency generator thru the cue and monitored the back end with a Barcus Berry pickup I borrowed from my Bass Fiddle. All blanks were tested without the pins installed.

The pattern between a maple cue exterior woods and one done with Ebony shows amplitude and frequency patterns that have a very similar profile. These two woods were the fartherest pattern difference but only about 10%. The other combos were are less.

End results from my test experiments is tha cues built on a core play very similar concern feedback.

I also tested some Ajoint cues with different combos and they show no similar pattern. Scrambled eggs. So they all played and felt very different.

All testing was done in 2007 and this was the reason I went to full coring on a 3/4" laminated maple dowel.

I core with gorilla poly glue which also produces a quieter hit. When i cored with West System it had more of a ping. Conversely if you like a loud cue with a ping my cues are not for you. My friend Wendell Weir advised me when I started building cues that he liked maple cues because they were quiet and he felt the hit right up his arm with his milk the cow

Stroke.

No way is right or wrong, just different. The cue maker has many choices.

I like your test setup. I've thought of doing something similar with ultrasound, as that method is often used in wood analysis outside the cue industry:

Very cool!I like your test setup. I've thought of doing something similar with ultrasound, as that method is often used in wood analysis outside the cue industry:

Good if it's cut from the same board.

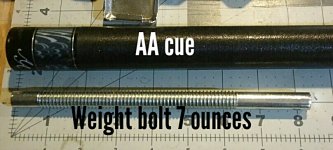

But, no way to add weight in the middle.

You end up adding too much weight on top and bottom to get to 15 oz.

Attachments

What did use as a transducer to impart the 440 Hz tone?IMO, a 1 3/8 laminated blank will have the most consistant hit and won't warp.

I build my cues on a 3/4" laminated 30" dowel. The difference in the hit only varies and 5 to 10 percent depending on the combo woods I use.

I took a 2 trace oscilloscope and put a 440 hertz concert A tuning frequency thru 8 different blanks from my frequency generator thru the cue and monitored the back end with a Barcus Berry pickup I borrowed from my Bass Fiddle. All blanks were tested without the pins installed.

The pattern between a maple cue exterior woods and one done with Ebony shows amplitude and frequency patterns that have a very similar profile. These two woods were the fartherest pattern difference but only about 10%. The other combos were are less.

End results from my test experiments is tha cues built on a core play very similar concern feedback.

I also tested some Ajoint cues with different combos and they show no similar pattern. Scrambled eggs. So they all played and felt very different.

All testing was done in 2007 and this was the reason I went to full coring on a 3/4" laminated maple dowel.

I core with gorilla poly glue which also produces a quieter hit. When i cored with West System it had more of a ping. Conversely if you like a loud cue with a ping my cues are not for you. My friend Wendell Weir advised me when I started building cues that he liked maple cues because they were quiet and he felt the hit right up his arm with his milk the cow

Stroke.

No way is right or wrong, just different. The cue maker has many choices.

Sometimes the amount of BS I read is just beyond disbelief.

You must be new to the internet.Sometimes the amount of BS I read is just beyond disbelief.

Can you explain how a hit varies by 5%?IMO, a 1 3/8 laminated blank will have the most consistant hit and won't warp.

I build my cues on a 3/4" laminated 30" dowel. The difference in the hit only varies and 5 to 10 percent depending on the combo woods I use.

I took a 2 trace oscilloscope and put a 440 hertz concert A tuning frequency thru 8 different blanks from my frequency generator thru the cue and monitored the back end with a Barcus Berry pickup I borrowed from my Bass Fiddle. All blanks were tested without the pins installed.

The pattern between a maple cue exterior woods and one done with Ebony shows amplitude and frequency patterns that have a very similar profile. These two woods were the fartherest pattern difference but only about 10%. The other combos were are less.

End results from my test experiments is tha cues built on a core play very similar concern feedback.

I also tested some Ajoint cues with different combos and they show no similar pattern. Scrambled eggs. So they all played and felt very different.

All testing was done in 2007 and this was the reason I went to full coring on a 3/4" laminated maple dowel.

I core with gorilla poly glue which also produces a quieter hit. When i cored with West System it had more of a ping. Conversely if you like a loud cue with a ping my cues are not for you. My friend Wendell Weir advised me when I started building cues that he liked maple cues because they were quiet and he felt the hit right up his arm with his milk the cow

Stroke.

No way is right or wrong, just different. The cue maker has many choices.

DeeDeeCues

Well-known member

Sooooo many questions.

Sooooo positive I don't want to waste my time reading the 'answers'.

Sooooo positive I don't want to waste my time reading the 'answers'.

It would be like watching Rambo II then Rambo III.Sooooo many questions.

Sooooo positive I don't want to waste my time reading the 'answers'.

Body counts just pile up.

But, no way to add weight in the middle.

You end up adding too much weight on top and bottom to get to 15 oz.

If you were to make one yourself and knowing you cannot add weight in the middle, is there a wood combo that you can use to get to 15oz, say Maple and Cocobolo ?

GolfProPoolAmateur

Member

Just got my new cue, a laminated P3, and couldn’t be happier.