Was down in the shop tonight. Sitting on the chair doing a clean up of a small

tail stock, I had a idea - possibly not new and may be used already:

In stead of moving the tailstock for each "turn" using the coring drill,

it struck me - why do I not just mount the drill in a beefy tool holder on my cross

slide? In this way I can use a nice auto feed and not having to do this in steps

of the tailstock travel.

I'm using a large quick change tool holder - that one I tested/described

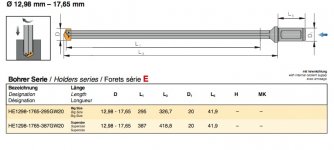

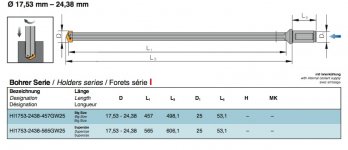

up here earlier. The "Round tool" holder is never in use since the holder is to

big (rooms tools of OD<25-30mm). So this could hold the coring drill.

Any one tried it? I guess it might be a thing many use and not new

in this respect?

I have no coring drill to test it out with at the moment so I have no conclusion

in respect of vibrations or other potential bad things I may have forgotten

What do you think ?

Kent

tail stock, I had a idea - possibly not new and may be used already:

In stead of moving the tailstock for each "turn" using the coring drill,

it struck me - why do I not just mount the drill in a beefy tool holder on my cross

slide? In this way I can use a nice auto feed and not having to do this in steps

of the tailstock travel.

I'm using a large quick change tool holder - that one I tested/described

up here earlier. The "Round tool" holder is never in use since the holder is to

big (rooms tools of OD<25-30mm). So this could hold the coring drill.

Any one tried it? I guess it might be a thing many use and not new

in this respect?

I have no coring drill to test it out with at the moment so I have no conclusion

in respect of vibrations or other potential bad things I may have forgotten

What do you think ?

Kent