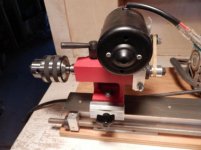

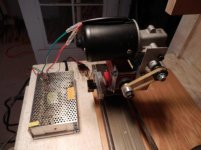

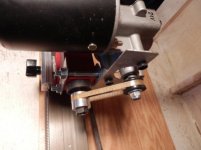

i got tried of cranking the screw style tailstock when coreing, so i rube goldberg this set up. it is a gear reduction 24 volt 2 amp dc reversable motor, a 110 ac to 24 volt dc 10 amp converter, an forward, reverse, and off switch. a few pulleys, a sewing machine belt and a homemade bracket. i made the bracket from a piece of aluminum angle. it was easy to cut and i had to make many adjustments to make everything fit. i will replace the bracket with one made from steel as i now have a template.

it is setting on this end of the delux just for the photos.

i do need help to finish this project, i can now core very soft woods. the unit will turn at approx one revolution per second, but thats too fast for harder woods in my opinion. i want to install a speed controler, but don't really know what type to use and where to install it.

all criticisms, suggestions, and comments welcomed.

it is setting on this end of the delux just for the photos.

i do need help to finish this project, i can now core very soft woods. the unit will turn at approx one revolution per second, but thats too fast for harder woods in my opinion. i want to install a speed controler, but don't really know what type to use and where to install it.

all criticisms, suggestions, and comments welcomed.