Players warranty

I had a players shaft warp like a broken finger, at least a 15 degree bend.

I called up players and ran down all the info like who and when did I bought the cue.

And they said go ahead and send it in.

The company that I bought it from was closing its doors when I bought it, Keystone cue and cushion.

After the cue got there they denied the warranty because of where I bought it......

I told them to send me my cue back and the said they threw it away..................

There is a good chance the factory would of denied your warranty for any reason they could come up with anyway.

Curious as to the thoughts of anyone who 'd like to chime in.

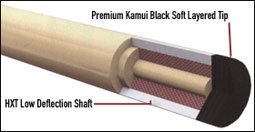

I had the tip on my HXT skinny shaft replaced this week by a local cue repair guy. While trimming the new tip, the tenon on the HXT shaft snapped. Without consulting me, the repair guy cut a new tenon and installed a new ferrule. For those who may be unaware, the low deflection technology in an HXT shaft is, in fact, the ferrule. It's a hollow, polymer filled design. So, the shaft is no longer low deflection.

I called Players today to find out if the shaft would be repaired or replaced under warranty. I was told it probably would have been if I'd have just sent the shaft and broken tenon/ferrule/tip in for examination. However, since the repair man took it upon himself to fix it, the shaft is no longer covered under warranty.

I'm not particularly mad at anyone involved. Things happen and I think the repair guy tried to do what he could to make the situation right at the time. However, he is apparently unfamiliar with the correct process for replacing a tip on an HXT ferrule.

Similarly, I can understand Players position. There is no way for them to determine what exactly happened. But, I do have the ferrule with the tenon inside and a partially trimmed tip installed. It seems fairly obvious as to what transpired here. And it seems to me like a problem that should be covered under warranty.

So, what do you think? Stop recommending the HXT shaft? Not because it's not a good shaft, but this could happen to any repair guy, unknowingly voiding a customers warranty. At very least any recommendation of these shaft now requires a footnote for when tip replacement time comes around. Or, do I "blame" the repair man? He did a very nice job with the new ferrule and tip by the way, so he seems competent enough. Perhaps he should have recognized he was in unfamiliar territory with this shaft and acted accordingly.

Thoughts?

I had a players shaft warp like a broken finger, at least a 15 degree bend.

I called up players and ran down all the info like who and when did I bought the cue.

And they said go ahead and send it in.

The company that I bought it from was closing its doors when I bought it, Keystone cue and cushion.

After the cue got there they denied the warranty because of where I bought it......

I told them to send me my cue back and the said they threw it away..................

There is a good chance the factory would of denied your warranty for any reason they could come up with anyway.

Last edited: