Thanks for your comment and advice, and do tell what I have missed. Maybe I can still make a correction.You almost have the extensions correct, but you missed a key point on them.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Corner pocket miter angles

- Thread starter realkingcobra

- Start date

Nope, you're going to have to do your extension over again if you want to right.Thanks for your comment and advice, and do tell what I have missed. Maybe I can still make a correction.

The only things that come to mind now are:Nope, you're going to have to do your extension over again if you want to right.

1. featherstrip groove on the extension bit, which I have done, and

2. maybe the back of the extension bit is not going far enough? To my mind this is not the case, since it would interfere with the pocket, which I then could not attach properly.

Other than that, I'm at a loss. Could you let me know what I have missed, please?

The extension has to follow the natural angle of the subrail it's attached to, and that means all the easy back to the finish of the rail. Instead of a 90° end on the extension, it should be a 51° miter, and be notched out to fit the featherstrips.The only things that come to mind now are:

1. featherstrip groove on the extension bit, which I have done, and

2. maybe the back of the extension bit is not going far enough? To my mind this is not the case, since it would interfere with the pocket, which I then could not attach properly.

Other than that, I'm at a loss. Could you let me know what I have missed, please?

Now when you add the pocket facings, they go all the way back to the edge of the extension, and are cut 90° flush with the extension.

And yes, your pocket will still fit in place, it just tucks behind the extension

Ok I see what you mean now, looking at the picture. I think the picture I posted showed the shortest extension, and even with that one I had to make a cut on it to accommodate the pocket. But yeah it could be longer at the back, I get your point. And thank you very much for explaining this to me.

Is it possible that since I'm cutting the extension with a new miter angle which cuts away most of the wood from the back of the facing-side of the extension anyway, I might still be okay? I'll have a look tomorrow, and if it doesn't work out to be as you explained, I will do the extensions as many times as it takes to make them as close to perfect as I can make them.

Again, thank you for your time and advice. Maybe I'll post new pics later on

Is it possible that since I'm cutting the extension with a new miter angle which cuts away most of the wood from the back of the facing-side of the extension anyway, I might still be okay? I'll have a look tomorrow, and if it doesn't work out to be as you explained, I will do the extensions as many times as it takes to make them as close to perfect as I can make them.

Again, thank you for your time and advice. Maybe I'll post new pics later on

Right in the end is all that matters.Ok I see what you mean now, looking at the picture. I think the picture I posted showed the shortest extension, and even with that one I had to make a cut on it to accommodate the pocket. But yeah it could be longer at the back, I get your point. And thank you very much for explaining this to me.

Is it possible that since I'm cutting the extension with a new miter angle which cuts away most of the wood from the back of the facing-side of the extension anyway, I might still be okay? I'll have a look tomorrow, and if it doesn't work out to be as you explained, I will do the extensions as many times as it takes to make them as close to perfect as I can make them.

Again, thank you for your time and advice. Maybe I'll post new pics later on

I think I understand measuring the angle opening.Factory is 142 miter, 12 degrees down angle.

What's the "Down Angle"

Excuse my ignorance.

Vertical angle, perpendicular to the cushion. The top of the rail will overhang the bottom by a certain degree. Usually around 12.I think I understand measuring the angle opening.

What's the "Down Angle"

Alright, so this is where I'm at now. Had a talk with Glen last night and got some very helpful tips and advice on how to proceed

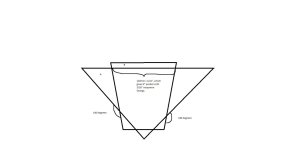

The picture shows roughly how the miter angles are going to change. The corners are going to be 4", but I don't know if the sides should be 4 1/2" or 4 3/4".

The picture shows roughly how the miter angles are going to change. The corners are going to be 4", but I don't know if the sides should be 4 1/2" or 4 3/4".

Attachments

Diamond once told me in a email that side pockets shouldn't be smaller than 4.75Alright, so this is where I'm at now. Had a talk with Glen last night and got some very helpful tips and advice on how to proceed

The picture shows roughly how the miter angles are going to change. The corners are going to be 4", but I don't know if the sides should be 4 1/2" or 4 3/4".

This. 4.5" sides are too small. My pocket dimensions are 4.125" corners and 4.875" sides.Diamond once told me in a email that side pockets shouldn't be smaller than 4.75

Are they cut to 4" now without the facings?Alright, so this is where I'm at now. Had a talk with Glen last night and got some very helpful tips and advice on how to proceed

The picture shows roughly how the miter angles are going to change. The corners are going to be 4", but I don't know if the sides should be 4 1/2" or 4 3/4".

Thanks for your comments guys.Are they cut to 4" now without the facings?

The extensions are not yet cut to the correct miter angle. I needed to make some adjustments per Glen's advice first.

I need to take the facings into account when aiming for that 4 inch cut, I am aware of that.

So the 4.5 inch side is too tight, 4.75 is the tightest I should be aiming for as I understand...

sides should 3/4 more than the corners imoThanks for your comments guys.

The extensions are not yet cut to the correct miter angle. I needed to make some adjustments per Glen's advice first.

I need to take the facings into account when aiming for that 4 inch cut, I am aware of that.

So the 4.5 inch side is too tight, 4.75 is the tightest I should be aiming for as I understand...

Coos Cues

Coos Cues

It looks like Pat Sheehan did his butchery on them to me. Except the cloth isn't sagging all over them.

I have seen Glen's sanding disc setup in action and observed how it straightens stuff out. And I mean stuff like right off the diamond assembly line. After he cuts a pencil line in half right down the middle with it pre marked with his angle gauge a person's eyes come wide open. I could post pictures of it but not sure if Glen wants that out there.

I have seen Glen's sanding disc setup in action and observed how it straightens stuff out. And I mean stuff like right off the diamond assembly line. After he cuts a pencil line in half right down the middle with it pre marked with his angle gauge a person's eyes come wide open. I could post pictures of it but not sure if Glen wants that out there.

Fine with me buddyIt looks like Pat Sheehan did his butchery on them to me. Except the cloth isn't sagging all over them.

I have seen Glen's sanding disc setup in action and observed how it straightens stuff out. And I mean stuff like right off the diamond assembly line. After he cuts a pencil line in half right down the middle with it pre marked with his angle gauge a person's eyes come wide open. I could post pictures of it but not sure if Glen wants that out there.

Sounds about right to me as well.sides should 3/4 more than the corners imo

I should propably have a jig to mark up the new miter angles, so that my pockets are all the same, for better or worse.

Below is a mockup of that, consisting of 2 pieces; part A which is just a right angle piece, and part B which has the pocket shape. Part A will be laying flat on the slate, making sure the rails are 90 degrees to each other, and part B is fixed on top of that, giving me the shape to mark the angles on the rails and cushions. I have a buddy who is a carpenter, he can make the jig for me (and propably has a better idea for a jig anyway) and make sure the 2 pieces are oriented correctly relative to each other.

Then I'll sand the rails and cushions with the 50 grit sanding dish method Glen suggested. Obviously the side pockets will have to be done with a different jig. And when I'm done with all this, I expect having to start all over again after making some mistake

Attachments

Last edited: