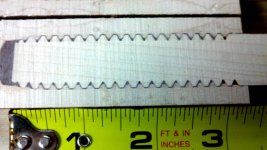

Well, maybe it's just me... but that sure as hell doesn't look like 29" of threads.

You know, I think it's become kind of apparent that when you opened this thread, even though you were pretending to seek the opinions of others, in reality you just want to shove YOURS down everyone's throats.

IN MY OPINION, the Beal threading system has plenty of uses in any number of woodworking applications. I bought one many, many years ago and experimented with it a great deal. Ultimately I chose to not use it because I feel the methods I DO use produce superior results.

That answers your original question, and is my honest (and learned) opinion. Don't like it? Frankly, at this point I don't really give a shit.

TW[/SIZE]

I originally asked this question, without revealing that I had already bought it and played a bit with it because, #1) I knew there would be people that will scoff and make jokes. #2)I wanted to find out if anyone else had used it and their thoughts. I have received a few PM's about it with some very positive results and I feel that I have received some honest feedback. All public posts have been either poking fun or negatively based, quite contrary to the pm's I have received. Your original post was fine, and appreciate it. I do begg to differ as to who's shoving what down whose throats....I am not shoving anything down anyone's throat, if anything, people with

pre-formed ideas have done that with their opinions and jokes. I have then asked

If this is so useless, then give an alternative method on how to thread a 29" dowel with something other than this and so far no one has answered that in public, not even you in your greatness. I didn't ask if I should do it, I asked how to do it, big difference IMO. BTW, good call on the picture, you can tell about 2.75" from 29", gold star for your forehead ....it was a test dowel DA.

So why are you so pissed? I am interested in doing a full threaded core and have posed a possible way to do it, but instead of any real help, all that is given is resistance and jokes by people such as yourself. No one has disputed my idea of changing the insert and using the 'standard' threading, no one has said that they have done that and it didn't work, etc....so At this point, I'm still at square one, until I machine my own insert and try it. Now at the risk of sounding ungrateful, you are excused from this thread, as you apparently have no usefull insight to offer, so POOF....Be Gone. I'm sure you have something better to do than troll here looking for arguments. You came in by your own decision, and can leave by the same.....in the words of my grandfather...."don't let the door hit ya where the good Lord split ya..."

For all those that have pm'ed me, I thank you and will let you know how it goes with the homemade inserts.

As far as I'm concerned Thread is closed, nothing to see here... move along people.

Have a nice night everyone.

Dave