Eric,

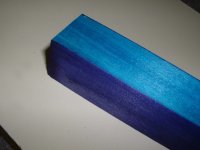

I just received a picture of the veneers fairly close up on a Spain blank Balabushka. It's pretty easy to see that they are stacked. Not only that, they are all stacked the same direction! It's way too big to post and if I make it smaller. it's harder to see.

So, I totally agree with you. If they are done right or not is what counts. I have seen cues where they were done so well it was hard to tell. I'm also not sure recuts would change the hit much either. Again, provided everything was glued and machined properly.

Hello Royce, I have a copy of Burtons "The recollections of Burton Spain" Making Point Blanks.

According to Burton he made them both ways depending if he was making full length blanks or short balnks, below is some pages out of Burton's book.

If anyone would like some fullsize photo's that cover how Burton Built Geogre Balabushka's blanks I will send them to your email address, Burton go's into a great deal of detail.

Hope this helps