I really like the caswell buffer!

I've talked to the owner of buff polish and grind quite a bit over the years. He's considered to be one of the most knowledgeable people in the polishing industry. His website is

www.buffpolishgrind.com. This guy is amazing! I have watched him take 220 grit sanding scratches out of stainless steel with 1 buffing step!

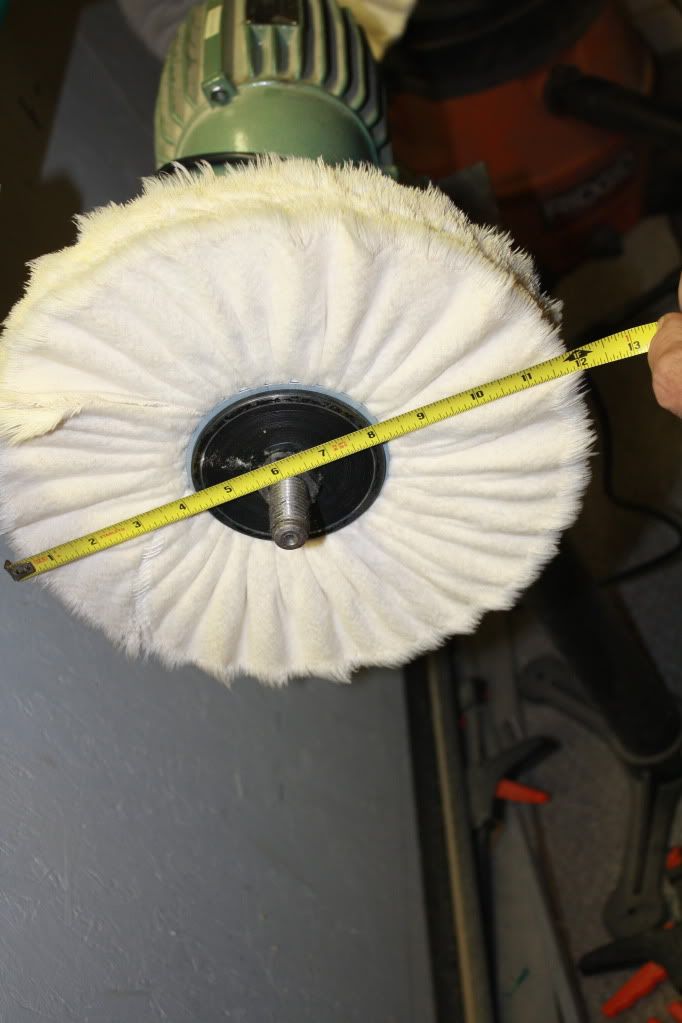

Anyway, he recommended to me that I try to achieve a surface feet per minute of about 3770. Actually, 1200 rpm with 12" wheels is almost exactly that. But, when the wheels wear off a little, the speed is slower than 3770. I use to have a variable speed setup that would hold speed even under load. I tried all different speeds, and found that I had better luck with a little higher speed. I like anywhere from 3900 up to about 4500. Faster than 4500, and it's too easy to burn the finish away, and slower than 3770 and I need to push a little too hard on the wheel to get a little heat. My setup with the regular electric motors gives me 4500 on the new 10" wheels. And, as the wheels wear, the speed drops down to 3800 at about 8.5" on the wheels.

A couple of things to think about. I like to rotate the cue as I'm buffing it, so we spin it with an air drill. We spin it pretty slow, but the spinning is pretty helpful. It really makes it easy to work the heat to just the right amount and move down the cue slowly. If you move faster, the heat is less, and slower will raise the heat up. Also, if your turn the cue rotation against the spinning wheel, you will effectively increase the SFM. Conversely, if you spin with the wheel you will decrease the SFM. We use this to our advantage. If we are having trouble getting too hot when the wheels are bigger, we go with the wheel. Later, when the wheels are smaller, it can be harder to get that "Pop" with the final buff. That's when we go against the spin of the wheel to raise the SFM and get the heat back up easier.

In the end, there is no perfect setup, and many different things will produce excellent results. You just have to figure out the steps for you setup and write it down so you won't forget it.