Tom, do you have any figures regarding the viscosity of your new product; say, related to Ford cup #4, or Zahn 2 cup? Thanks

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Clear Coat about ready

- Thread starter TomHay

- Start date

Tom, do you have any figures regarding the viscosity of your new product; say, related to Ford cup #4, or Zahn 2 cup? Thanks

Sure,

Brookfield Viscosity @25°C RVT #3 @12 rpm 1000

Tom, do you know how long before full cure? Are you cutting the product with anything ?........Looks great I'm in too...............Ray

At this point 24 hours but at this point things may change a little.

Sure,

Brookfield Viscosity @25°C RVT #3 @12 rpm 1000

You can't strump Tom with technical details!

:thumbup:

Gary

It stumped me.

All I know is that.

I put it on.

It dries.

It looks good.

Finishing for Dummies is me.

Tom. What would the shelf life be on this new product. Same as most finishing products

or too early to tell yet.

All I know is that.

I put it on.

It dries.

It looks good.

Finishing for Dummies is me.

Tom. What would the shelf life be on this new product. Same as most finishing products

or too early to tell yet.

You can't strump Tom with technical details!

:thumbup:

Gary

I'm not trying to stump Tom. I just bought the gun Pescodamen Randy recently discussed (Iwata lph-80), with the 1mm nozzle he uses. The ph80 literature specifies it is appropriate for viscosity of 15 seconds on Zahn 2 cup. I was hoping to discover that my new gun would work with Tom's new product. But I don't have a clue - can't comprehend his viscosity numbers.

I'm not trying to stump Tom. I just bought the gun Pescodamen Randy recently discussed (Iwata lph-80), with the 1mm nozzle he uses. The ph80 literature specifies it is appropriate for viscosity of 15 seconds on Zahn 2 cup. I was hoping to discover that my new gun would work with Tom's new product. But I don't have a clue - can't comprehend his viscosity numbers.

Sorry bud, I am an old guy that has to do things by ASTM tests and the ASTM test for viscosity does not use a Zahn. From your description it is a cup drip test, let me look into it please.

Sorry bud, I am an old guy that has to do things by ASTM tests and the ASTM test for viscosity does not use a Zahn. From your description it is a cup drip test, let me look into it please.

Can adhesion ,shear and hardness tests be done on it compared to 2-part clear, Tom ?

Thanks.

I don't have time to look into this right now, running late to work, but maybe this will help. Maybe not too..

http://www.gardco.com/pages/viscosity/vi/ez.cfm

http://www.gardco.com/pages/viscosity/vi/ez.cfm

Watching with interest Tom. You mentioned this will be pre reacted, are we to understand this as meaning it will cross-link as it cures, and how should it compare in terms of chemical resistance to a 2k urethane?

As a floor coating it is at independent testing labs as I type. As an Aliphatic Polyurea I have a pretty good idea from similar formulations that for chemical resistance it will blow the doors off a 2K Urethane, Polyurea is known for secondary containment.

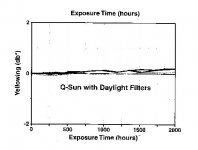

Recently got the UV filtering tests back.

swami4u

Banned

As a floor coating it is at independent testing labs as I type. As an Aliphatic Polyurea I have a pretty good idea from similar formulations that for chemical resistance it will blow the doors off a 2K Urethane, Polyurea is known for secondary containment.

Recently got the UV filtering tests back.

View attachment 329961

New market for you? One you haven't thought about yet???? :thumbup:

Yacht exterior wood? If it has true uv protecting qualities, better then anything on the market, then there you go. Just send a case of tips for the suggestion! JK

Good luck with it!

New market for you? One you haven't thought about yet???? :thumbup:

Yacht exterior wood? If it has true uv protecting qualities, better then anything on the market, then there you go. Just send a case of tips for the suggestion! JK

Good luck with it!

It's a pretty good idea, but most brightwork outside gets retouched regularly anyway. I don't know what "yachts" use, but I've tried everything on a boat that really gets used and nothing lasts...especially on mahogany.

If you really want to try that market, I can arrange a trial with a sportboat(meaning a boat that fishes with customers 200+ days out of the year). If it lasts on one of those for more than a year AND doesn't peel or turn yellow(meaning a pain in the ass removal), then you will have something. What normally happens is sections begin to get damaged and water gets underneath. Paint starts lifting and the wood underneath discolors and becomes somewhat unsightly, normally required a complete refinish every year. I think the Independence used a clear on their rails, but I don't know how it held up. We used LP clear once and it needed to be redone the next year. In fact, I don't know of any sportboat that doesn't refinish rails every year(unless they don't mind looking like crap). There is no better test..

Last edited:

It's a pretty good idea, but most brightwork outside gets retouched regularly anyway. I don't know what "yachts" use, but I've tried everything on a boat that really gets used and nothing lasts...especially on mahogany.

If you really want to try that market, I can arrange a trial with a sportboat(meaning a boat that fishes with customers 200+ days out of the year). If it lasts on one of those for more than a year AND doesn't peel or turn yellow(meaning a pain in the ass removal), then you will have something. What normally happens is sections begin to get damaged and water gets underneath. Paint starts lifting and the wood underneath discolors and becomes somewhat unsightly, normally required a complete refinish every year. I think the Independence used a clear on their rails, but I don't know how it held up. We used LP clear once and it needed to be redone the next year. In fact, I don't know of any sportboat that doesn't refinish rails every year(unless they don't mind looking like crap). There is no better test..

Having grown up in south Florida (Miami) and having a family sail boat( until hurricane Andrew came through), I can agree that Nothing lasts the year. Salt water and sun will eat the finish on the bright work. I HATED refinishing a wooden mast that was about 40 feet high !

swami4u

Banned

It's a pretty good idea, but most brightwork outside gets retouched regularly anyway. I don't know what "yachts" use, but I've tried everything on a boat that really gets used and nothing lasts...especially on mahogany.

If you really want to try that market, I can arrange a trial with a sportboat(meaning a boat that fishes with customers 200+ days out of the year). If it lasts on one of those for more than a year AND doesn't peel or turn yellow(meaning a pain in the ass removal), then you will have something. What normally happens is sections begin to get damaged and water gets underneath. Paint starts lifting and the wood underneath discolors and becomes somewhat unsightly, normally required a complete refinish every year. I think the Independence used a clear on their rails, but I don't know how it held up. We used LP clear once and it needed to be redone the next year. In fact, I don't know of any sportboat that doesn't refinish rails every year(unless they don't mind looking like crap). There is no better test..

Yep, i helped build the 2009 Volovo Ocean Race Puma race boat. (pre preg laminations) I was just a newb learning the aerospace lamination techniques then...But my finger prints are all over that boat. :grin:

I do have a little experience with sail boats. All i can tell Tom is Cetol is the best option available now for UV protection of teak in FL.

But, what sailors DONT like about it, it changes the look of the teak. (in short) Gives the teak a more orange/fake look.

If this product can outlast Cetol in Miami, and not change the look of varnished teak, I will take it to Miami full time, and market it myself!

Put me on the list for a bottle please, i have some old teak i will finish and send down to family, for a test vs Cetol.

Let me know via PM when you can sell me some please.

swami4u

Banned

Having grown up in south Florida (Miami) and having a family sail boat( until hurricane Andrew came through), I can agree that Nothing lasts the year. Salt water and sun will eat the finish on the bright work. I HATED refinishing a wooden mast that was about 40 feet high !

O' come now, we all know bright work re-finishing is a sailors greatest love!

Kinda along the lines of long board faring work! Try that 4 days str8, 10 hours a day, on a 70ft 100% carbon fiber, female hull mold. She is a bad bad gal!

Attachments

Last edited:

swami4u

Banned

Cetol has an amber cast to it like old fashioned varnish. Not really suitable for cues in my opinion. Nice stuff to have on a sailboat though.

Robin Snyder

Exactly, that's why if this product can offer the same uv protection on bright work, without the color changing problems of Cetol, its a home run.