Is there anyone who makes a pool cue without machines of any kind? I see that this thread has ignited another cnc-vs non-cnc debate.

No one responded to Thomas' statement that he could make an identical cue with CNC and without CNC.

So if the resulting cue is exactly the same where then is the reason for a distinction?

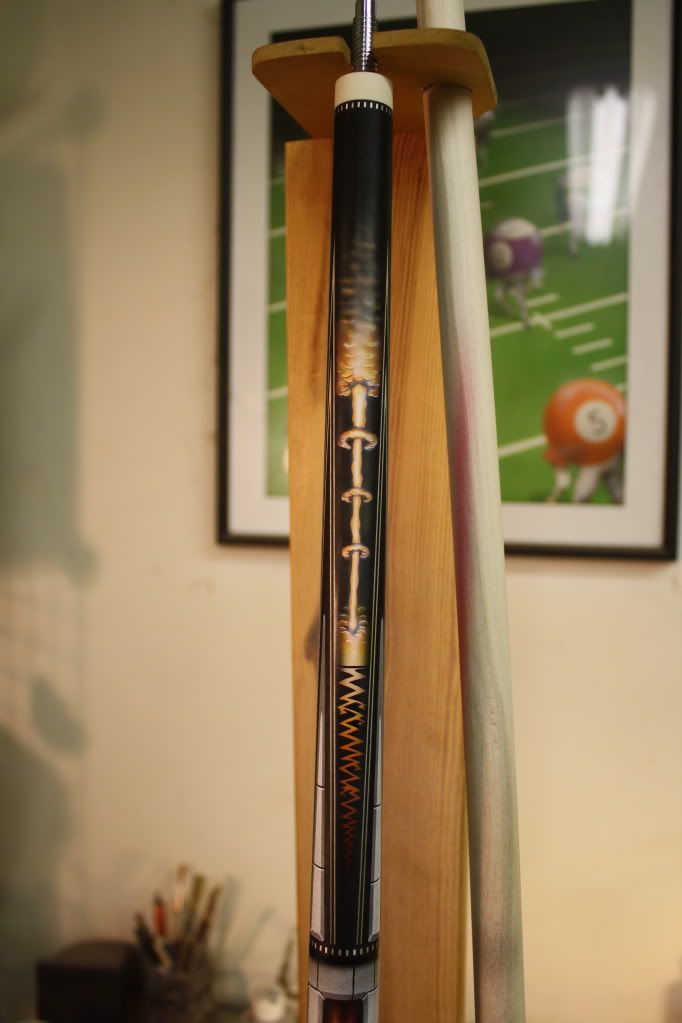

I sat watching the cuemaker's roundtable in 2009 and one of the things that they talked about is whose cue is it? Meaning that if you send a cue off to Sandra Brady or any of the other great scrimshanders and then it comes back fantastically decorated and that then is the focal point of the cue then whose cue is it really? At that point isn't the cue just the canvas that the "real" artist used to put their art on?

Is not the scrimshander or the airbrusher the same as the CNC in this case? To me the cue maker is USING something (or someone) other than his own two hands to make a cue that gets attention and accolades.

Why are we drawing divisions? The cue that is leading the cue of the year voting in the "official" thread is not a cnc-decorated cue. It's the Brunswick 360 Tribute by Gracio. So why the drama? Why the need to cause more divide among people?

I get this all the time, "your cases can't be better because you have employees, so and so makes them all by himself and that makes his cases better".........really?

When is the last time you bought a car, a refrigerator, or even a screwdriver that was made by ONE person?

At some point you have to look beyond the technique used and get to the actual item and admire it for it's existence regardless of how it came into being.

To me no cue counts as handmade unless the maker didn't use any power tools whatsoever. If all the energy came only from the cue maker's hands then it's hand made. Any time a machine was used then it's not hand-made anymore.

Some of you have this idea that CNC means throwing a chunk of wood into one end and a 456 overlapping point monster comes out the other end.

I have a laser cutter/engraver.

These parts were cut using it:

Just figuring out these parts cost me a whole day constantly refining the shape and physics to insure that they would be strong and functional and be able to fit into the seam's lacing properly. A whole day spent sitting at the laser tweaking, cutting, lacing, more tweaking, cutting lacing, more tweaking, more cutting, more lacing, in fact I got frustrated and quit and came back the next day.

Looks easy doesn't it?

But in fact when someone tried to copy this "by hand" they missed the important part which is the engineering. Anyone can draw out this shape and cut it "by hand". But if they don't understand the underlying engineering of exactly WHY it was this shape and not another way and why the rivets are just so and not somewhere else, then it's highly likely that their version, done by hand, will fail and break.

When we do any engraving we often have to do quite a lot of prep work before we even turn the laser on. Then once we THINK it's ready to go we then have to test it many times with different levels and different materials to find the combination that works best to achieve the effect we want.

Art is art. The tool to achieve it are only tools. If Michaelangelo had a six axis computer driven router to sculpt with then he would have created even more amazing sculpture than what he did using the tools available to him at the time. Creating division to say that one type of thing is "better" simply because it was created with one set of tools vs. another is petty to me.

Either the resulting cue is stunning because of how all the elements come together or it isn't. It's never good or bad because it was made with CNC or not. At least that shouldn't be the criteria. At the lowest level an indexer is a computer set up to rotate something at exactly predetermined intervals. So all of you doing indexed rings and indexed inlays are using a computer to drive part of your decorating.

If you want to make divisions then use the blue book's levels and have beauty contests based on those levels.

Lastly, since this post will be ignored and piss off the non-cnc crowd where are the all the Filipino cues that are made with hacksaw blades?

Don't those count toward the non-cnc "hand-made" contest? I am willing to bet that like the Ethiopians who dominate marathons that the Filipinos would own the "by hand" category of cue decoration.

Oh and Merry Christmas, Happy New Year and all that