cueporn

Banned

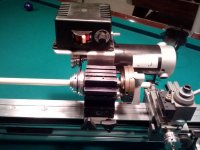

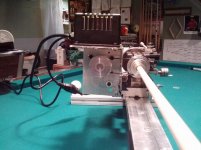

I built this 47 inch Taig based cue repair lathe using some of the 1.5" 8020 aluminium framing I had.

The dovetail bed is 3 pieces secured through the uchannel and into the 8020 with six 5/8" flat head bolts. It is super solid and portable, weighs about 35# based on my forearm curl test. It has 27" of Taig rack for moving the carriage knob pinion. The rack is set 5 inches in from the right hand side where the tailstock would be mounted, to maximize the length that is usable.

It comes with a brand new PennState 1/2 HP variable speed motor. I added a 10amp DPDT switch on the right hand side of tge contril box so the headstock rotation can be reversed. The switch is located in a good location, near the headstock where you can safely switch it off with your left hand. It turns the standard counterclockwise in the down position, off in the middle and clockwise in the up position.

The headstock is used and has a few dings on the black aluminium body, it is perfectly functional. The 3 jaw chuck opens wide enough to hold the butt of a cue, I believe it goes to 2.5". The spindle is 0.59" or 15 mm so the shaft of the cue can be passed through the back of the headstock , into the chuck and tipwork can be done with the tip just to the right of the chuck.

It can be used for tip replacement, ferrule installation, linen wrapping, shaft maintenance, butt cap work...really everything but tapering, but bars could be added.

This unit DOES NOT COME with the carriage, steady rest or tailstock included in the photos for demonstration purposes. Those items are readily available new or used if the buyer requires them. For those with full sized taig based lathes that are not portable, this setup will work with the components you have. So when you want to do repairs on the go at events you can easily do so. The headstock is mounted on a 1" riser block , so it matches up with components from tapering lathes tgat have 2 crossslides on the carriage and a riser under the tailstock. If the headstock riser isn't needed I can remove it.

Its a real nice setup, you will not be disappointed. I am asking $600 delivered for it. Payment by Paypal is encouraged, but I would take any form of payment. It will ship fully insured with tracking in 2 packages. The motor and headstock assembly in one

box. Then the bed will be seperate with the 2 feet disconected so in can fit nicely in a long triangular box. Any questions ask here or by PM.

The dovetail bed is 3 pieces secured through the uchannel and into the 8020 with six 5/8" flat head bolts. It is super solid and portable, weighs about 35# based on my forearm curl test. It has 27" of Taig rack for moving the carriage knob pinion. The rack is set 5 inches in from the right hand side where the tailstock would be mounted, to maximize the length that is usable.

It comes with a brand new PennState 1/2 HP variable speed motor. I added a 10amp DPDT switch on the right hand side of tge contril box so the headstock rotation can be reversed. The switch is located in a good location, near the headstock where you can safely switch it off with your left hand. It turns the standard counterclockwise in the down position, off in the middle and clockwise in the up position.

The headstock is used and has a few dings on the black aluminium body, it is perfectly functional. The 3 jaw chuck opens wide enough to hold the butt of a cue, I believe it goes to 2.5". The spindle is 0.59" or 15 mm so the shaft of the cue can be passed through the back of the headstock , into the chuck and tipwork can be done with the tip just to the right of the chuck.

It can be used for tip replacement, ferrule installation, linen wrapping, shaft maintenance, butt cap work...really everything but tapering, but bars could be added.

This unit DOES NOT COME with the carriage, steady rest or tailstock included in the photos for demonstration purposes. Those items are readily available new or used if the buyer requires them. For those with full sized taig based lathes that are not portable, this setup will work with the components you have. So when you want to do repairs on the go at events you can easily do so. The headstock is mounted on a 1" riser block , so it matches up with components from tapering lathes tgat have 2 crossslides on the carriage and a riser under the tailstock. If the headstock riser isn't needed I can remove it.

Its a real nice setup, you will not be disappointed. I am asking $600 delivered for it. Payment by Paypal is encouraged, but I would take any form of payment. It will ship fully insured with tracking in 2 packages. The motor and headstock assembly in one

box. Then the bed will be seperate with the 2 feet disconected so in can fit nicely in a long triangular box. Any questions ask here or by PM.

Attachments

Last edited: