You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Custom Spray Booth

- Thread starter jecues

- Start date

spray booth

check with Chris Hightower he has plans in his book

check with Chris Hightower he has plans in his book

Check with Jim Baxter. He posted pics some time ago.

He bought a small paint booth from EBay for models and other hobbies.

He extended both ends and it seems to work fine.

The pics are around here if you do a search for paint booths.

He bought a small paint booth from EBay for models and other hobbies.

He extended both ends and it seems to work fine.

The pics are around here if you do a search for paint booths.

i think it would be best if they were verticle.

What leads you to believe that vertical is a better way to go?

KJ

What leads you to believe that vertical is a better way to go?

KJ

Totally agree! If the cue is mounted vertically it would be immaterial if it was turning at 5 rpm or 3500 rpm, you still would get runs.

Dick

Runs with vertical hanging

I agree that runs should happen more with vertical hanging than horizontal hanging. So how does high production facilities do it with like house cues when they are dipping the cues with UV cure? Do they sand and polish the runs out after it cures?

I agree that runs should happen more with vertical hanging than horizontal hanging. So how does high production facilities do it with like house cues when they are dipping the cues with UV cure? Do they sand and polish the runs out after it cures?

A while back I posted pictures of my vertical spray booth (holds 2 shafts or 2 butts) and pretty much got blasted - not a problem, I accept and respect everyone's feedback here - that's how I have learned so much.

I also got some support, so it wasn't all one way.

I think the difference is in what you expect to get out of a spray application. Some like to lay on a spray coat as thick as you can (4-5 mils if memory servers me right) and let it level out as the cue shaft or butt slowly turns in the horizontal position. I have to apply lots of thin coats . I have occasionally gotten drips that I needed to sand out, but I've learned to go slowly.

Now, I'm not going to claim my finish has the deep lustrous look that others are able to achieve, but I think they mine pretty good.

So by far, the consensus is in favor of a horizontal booth and you should try to go that route - take advantage of the collective wisdom here.

And finally I should mention that one of my (MANY) projects in the back of my head is to look at converting my booth to horizontal and see what all the fuss is about!! In my small shop, 36-40 inches of horizontal wall space comes at a premium, hence the original design.

In my small shop, 36-40 inches of horizontal wall space comes at a premium, hence the original design.

My 2 cents!

Gary

I also got some support, so it wasn't all one way.

I think the difference is in what you expect to get out of a spray application. Some like to lay on a spray coat as thick as you can (4-5 mils if memory servers me right) and let it level out as the cue shaft or butt slowly turns in the horizontal position. I have to apply lots of thin coats . I have occasionally gotten drips that I needed to sand out, but I've learned to go slowly.

Now, I'm not going to claim my finish has the deep lustrous look that others are able to achieve, but I think they mine pretty good.

So by far, the consensus is in favor of a horizontal booth and you should try to go that route - take advantage of the collective wisdom here.

And finally I should mention that one of my (MANY) projects in the back of my head is to look at converting my booth to horizontal and see what all the fuss is about!!

My 2 cents!

Gary

If you get runs while spraying, you are spraying too much too fast. Check the specs of the finish you are using and it will tell you how thick each layer should be and how quickly you can recoat. Spraying too think of layers will cause problems, if not immediately, then it will down the road. Solvent trap being the obvious.

I agree that runs should happen more with vertical hanging than horizontal hanging. So how does high production facilities do it with like house cues when they are dipping the cues with UV cure? Do they sand and polish the runs out after it cures?

When JM gave me a tour at McDermott in the mid-80's they finished all their cue on a hanging (vertical) conveyor system.

They avoided runs because the cues had first been sprayed with a very light prep-coat that allowed them to receive and hold a static charge. The cues then passed through a chamber that was thick with a fog of finish, which clung to the cues (due to the static); following that they passed in front of a UV curing lamp system.

Little chance for runs with that system.

TW

When JM gave me a tour at McDermott in the mid-80's they finished all their cue on a hanging (vertical) conveyor system.

They avoided runs because the cues had first been sprayed with a very light prep-coat that allowed them to receive and hold a static charge. The cues then passed through a chamber that was thick with a fog of finish, which clung to the cues (due to the static); following that they passed in front of a UV curing lamp system.

Little chance for runs with that system.

TW

Yes Thomas, McDermott has one of the best finishes in the business, BUT, I've been told that they have 250K invested in their system. With that kind of investment they ought to have things nailed down pretty well! I think it's much easier to achieve a good finish with a small investment using the horizontal method. Just saying.......

Sherm

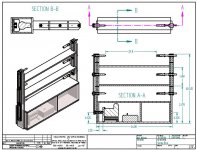

I built this over 5 years ago and I wouldn't change a thing on it. Variable speed motor with rubber belts. On the right side I have adjustable stop collars so I can move the entire cone support in case I'm spraying a longer than normal cue. My support cones slide on the shaft and are backed up with compression springs to keep pressure on the cue so it spins. The springs also have stop collars so I can reduce the pressure when spraying a shaft. I grab the pulley on the left so the belt slips on the cue that I'm spraying so i can spray a straight line. I then clock it a bit & spray again.

I built a 6x8 dedicated and controlled room. Explosion proof light and a fume exhauster that is strong enough to shut my door if I leave it cracked. My spray box is self contained so you could move it around in a small shop, but with over spray I can't see anyone spraying in the same area that all their other equipment is in. Too much collateral damage.

I built a 6x8 dedicated and controlled room. Explosion proof light and a fume exhauster that is strong enough to shut my door if I leave it cracked. My spray box is self contained so you could move it around in a small shop, but with over spray I can't see anyone spraying in the same area that all their other equipment is in. Too much collateral damage.

Attachments

I built this over 5 years ago and I wouldn't change a thing on it. Variable speed motor with rubber belts. On the right side I have adjustable stop collars so I can move the entire cone support in case I'm spraying a longer than normal cue. My support cones slide on the shaft and are backed up with compression springs to keep pressure on the cue so it spins. The springs also have stop collars so I can reduce the pressure when spraying a shaft. I grab the pulley on the left so the belt slips on the cue that I'm spraying so i can spray a straight line. I then clock it a bit & spray again.

I built a 6x8 dedicated and controlled room. Explosion proof light and a fume exhauster that is strong enough to shut my door if I leave it cracked. My spray box is self contained so you could move it around in a small shop, but with over spray I can't see anyone spraying in the same area that all their other equipment is in. Too much collateral damage.

Your's is very similar to mine. My shop is an old post office so the windows are steel and the panes crank out and they are high on the wall. I opened the slats on one window, installed an exhaust fan with the spray apparatus directly below and boxed it all in like a chimney. I have a filter on the door When I spray everything is sucked out very quickly. Mines primitive looking but works great as my booth is only about 4'X6' and the exhaust fan is 1650 cubic feet per minute.

I also have a UV set up below this. It is a lathe I put together and on a track also with a gear reduction motor. The UV light is in the corner of the room completely boxed in with a trap door that can be slid up so that this lathe can run into and past the light for curing but I am protected from seeing any of the lights harmful rays as they are contained in this tunnel. The light is set so that the cue goes past at exactly 3 inch distance.

Dick

Dick

Last edited:

Yes Thomas, McDermott has one of the best finishes in the business, BUT, I've been told that they have 250K invested in their system. With that kind of investment they ought to have things nailed down pretty well! I think it's much easier to achieve a good finish with a small investment using the horizontal method. Just saying.......

Sherm

+1...

Actually, I heard $1Million - but who's counting.

Dale(who lives in another neighborhood - the Neighbors neighborhood)

Sorry, I couldn't help it.

I have a 6 cue uv

Iam selling a 6 cue custom uv spray booth top of the line fan included all aliminum and brass 734-693-3177

Iam selling a 6 cue custom uv spray booth top of the line fan included all aliminum and brass 734-693-3177