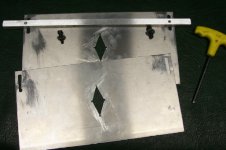

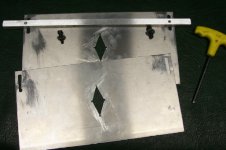

"License plate" jig for cutting diamond sights

Here is a simple, "license plate" adjustable jig for cutting different sizes of diamond sights. A two layer license plate jig works great for a lot of things because you can change the size of the cutout simply by sliding the two plates against each other. It is two identical sheets of 1/16" aluminum plate and a 1/2" x 1/2" guide bar, all held together with 1/4 x 20 cap screws. The diamond shapes were milled into the plates oversized so that by offsetting the two plates you can obtain different sizes of diamonds.

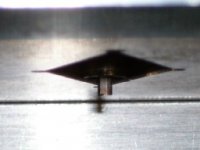

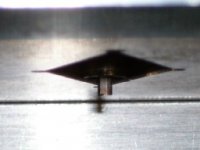

I use a laminate trimmer rather than a router because it is so much easier to use and with the minimal amount of material being removed from the diamond pocket it has plenty of power. The guide on the bottom of the router has been turned down so that it protrudes only 0.120" (slightly less than the 1/8" thickness of the two plates).

Here is a picture of the 1/8" solid carbide bit from the cutting side of the jig.

After setting the plate overlap and guide bar position (all three parts held together with the same two cap screws) I mount the jig to the rail with quick ratchet clamps.

In this rail, I used ebony diamonds set in white oak. Gives a really nice contrast when finished. For the final step, I use a tiny chisel (not shown) shaped just like the skinny, end points to cut out the rounded edge the router bit leaves. The finishing chisel is a relatively easy tool to make using a dremel and a small screwdriver as the blank.

The jig works just as well for MOP or abalone sights. One very important word of caution here:

I've noticed that the dust from grinding MOP and abalone sights is extremely toxic, especially the abalone. I cut and finish them wet using a wet lapidary saw so there is no dust.

Kerry

www.ridgebackrails.com