Hello,

I have spent a few hours using the search function and reading all I could find on this topic.

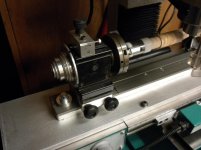

The setup would be a small taig headstock with indexer and a drilling tail stock attached to a piece of dovetail mounted on a 1/2" thick by 2" wide piece of aluminum.

What would be the best way to attach this to a milling table, a vise with swivel or attach it to the table without a vise and have it swivel on one end and a lock down setup on the other end?

Any advice will be greatly appreciated.

I have spent a few hours using the search function and reading all I could find on this topic.

The setup would be a small taig headstock with indexer and a drilling tail stock attached to a piece of dovetail mounted on a 1/2" thick by 2" wide piece of aluminum.

What would be the best way to attach this to a milling table, a vise with swivel or attach it to the table without a vise and have it swivel on one end and a lock down setup on the other end?

Any advice will be greatly appreciated.