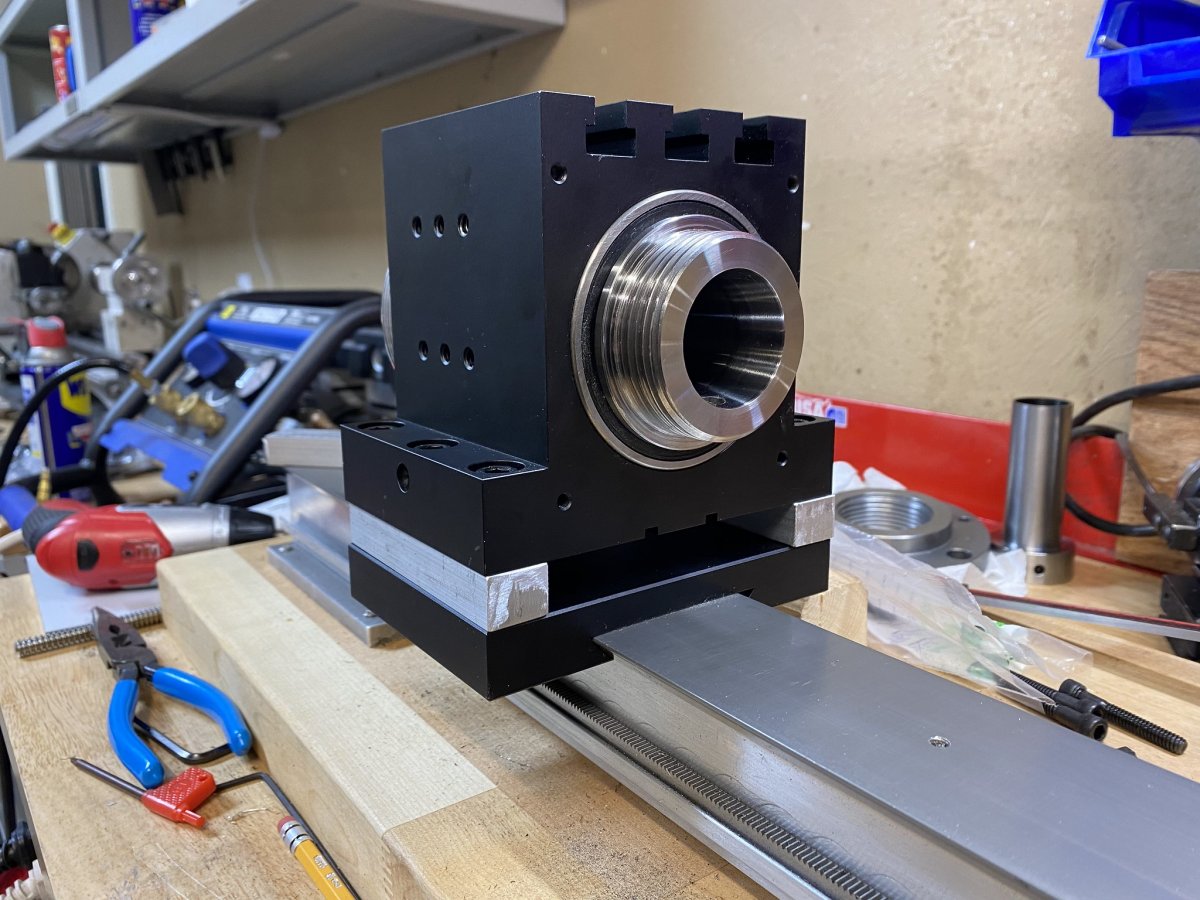

Since we started making cues a little over a year ago, I've often wondered about combining one of the Taig-based cue lathes with a larger headstock/chuck combination that would provide better torque from the added rotational mass, plus would do away with those annoying small chucks and Tommy-bars. I ended up coming across products from GlockCNC that are designed to work with Taig and Sherline mills and lathes, in particular their 5C headstock. This headstock is accompanied with spindle bearings that will easily handle the weight of a larger jaw chuck and is threaded 2-1/4x8 to accept available chuck backplates.

Unfortunately, the Taig lathe mount that I ordered sat the headstock at a goofy height (.41" higher than standard Taig fare), so I had to machine aluminum risers to match the height of my tailstock and steady rests that sit on 1" risers. I drilled and tapped the rear riser to mount my 3/4HP motor from MidAmerica (Todd Shultz).

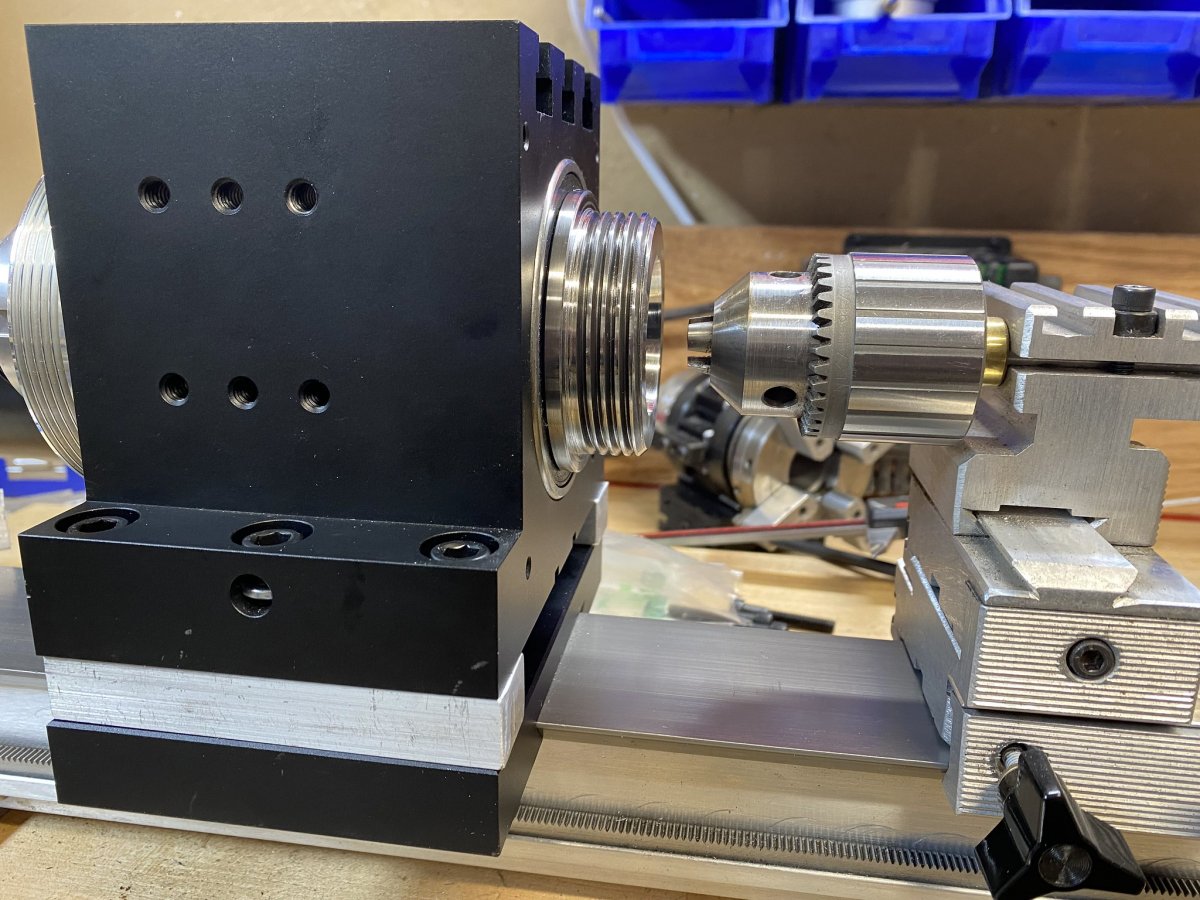

A 5" jaw chuck is the maximum size I could fit with the existing swing, and I found an inexpensive Shars 3-jaw on eBay that came with a threaded 2-1/4x8 backplate. The chuck had a smaller bore than I needed, so I used a boring bar to open it up a bit after installing (1.31" bore now to closely match spindle capacity). After installing the chuck, I put a dead center in it and hooked up an indicator, and it literally registered no discernable run-out whatsoever. I'm not particularly surprised the GlockCNC headstock would be that accurate, but I'm pretty surprised that my machining job on the chuck backplate was good enough to produce that.

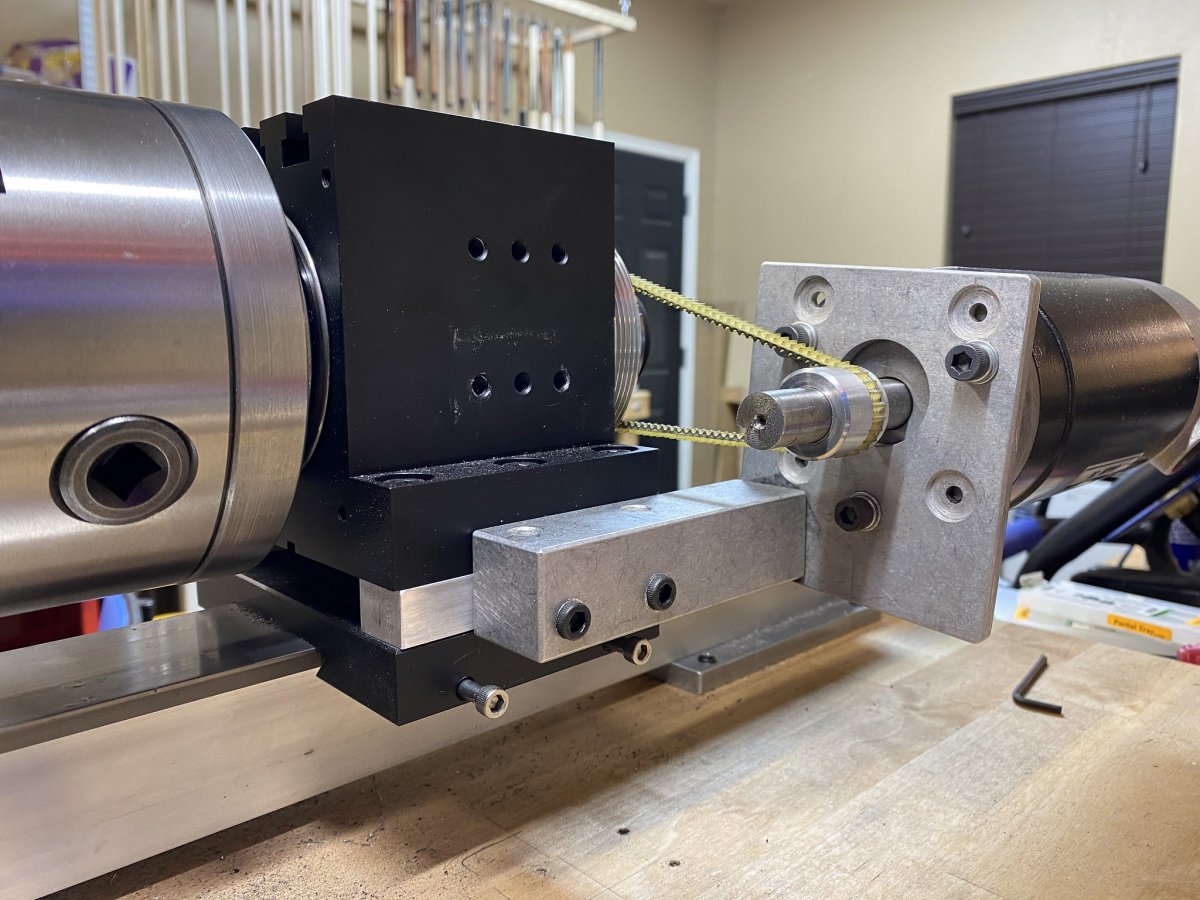

I ordered the headstock with a 2-step 5-rib pulley that accepts an automotive-type belt, but neglected to order a belt with it (but it's on the way now thanks to Amazon). Works fine so far with the v-belt the MidAmerica headstock used, so I tested the new set-up by turning a 5-rib drive pulley to use when my new belt arrives.

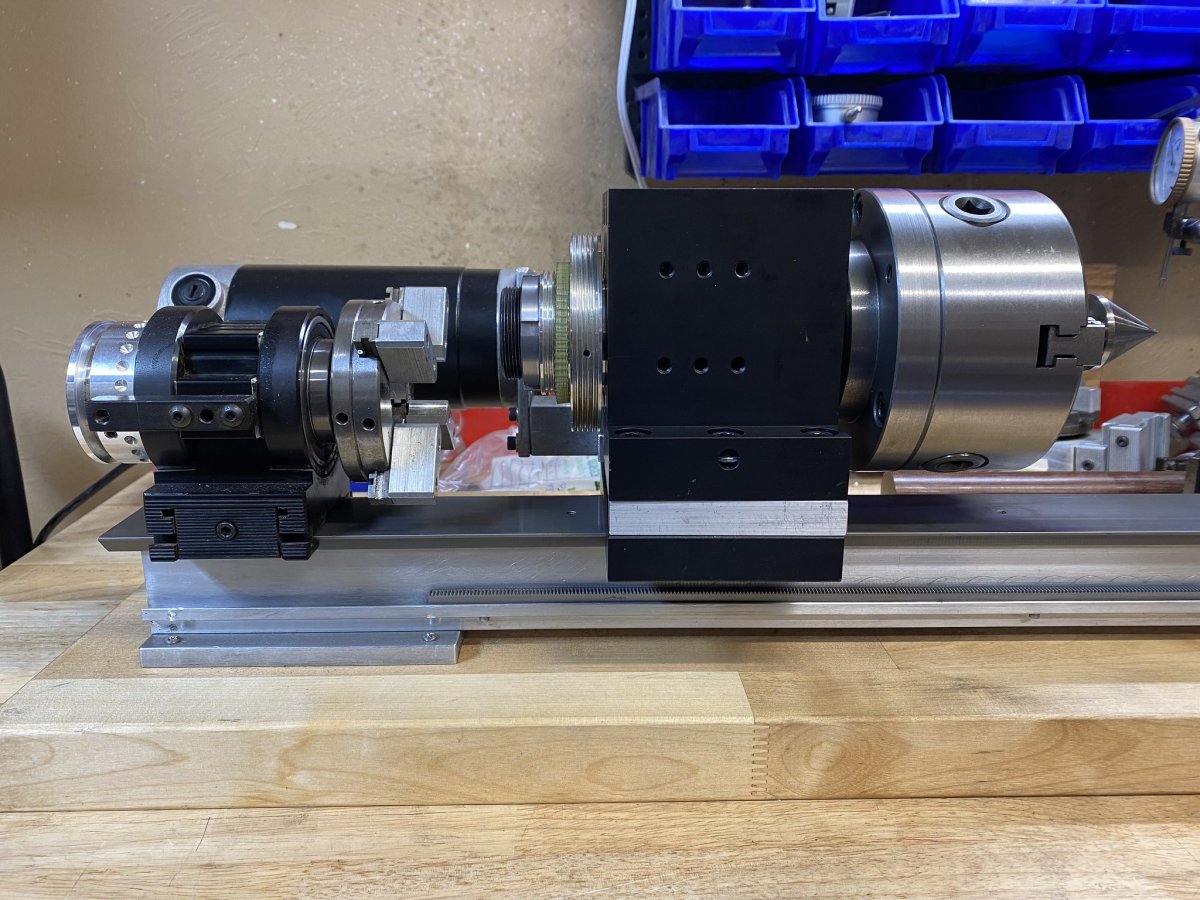

Comparison of the MidAmerica headstock and the GlockCNC:

That's all for now! Looking forward to actually doing some cue work on this today, but first it's Shop Vac duty to clean up a shop full of aluminum shavings....

Unfortunately, the Taig lathe mount that I ordered sat the headstock at a goofy height (.41" higher than standard Taig fare), so I had to machine aluminum risers to match the height of my tailstock and steady rests that sit on 1" risers. I drilled and tapped the rear riser to mount my 3/4HP motor from MidAmerica (Todd Shultz).

A 5" jaw chuck is the maximum size I could fit with the existing swing, and I found an inexpensive Shars 3-jaw on eBay that came with a threaded 2-1/4x8 backplate. The chuck had a smaller bore than I needed, so I used a boring bar to open it up a bit after installing (1.31" bore now to closely match spindle capacity). After installing the chuck, I put a dead center in it and hooked up an indicator, and it literally registered no discernable run-out whatsoever. I'm not particularly surprised the GlockCNC headstock would be that accurate, but I'm pretty surprised that my machining job on the chuck backplate was good enough to produce that.

I ordered the headstock with a 2-step 5-rib pulley that accepts an automotive-type belt, but neglected to order a belt with it (but it's on the way now thanks to Amazon). Works fine so far with the v-belt the MidAmerica headstock used, so I tested the new set-up by turning a 5-rib drive pulley to use when my new belt arrives.

Comparison of the MidAmerica headstock and the GlockCNC:

That's all for now! Looking forward to actually doing some cue work on this today, but first it's Shop Vac duty to clean up a shop full of aluminum shavings....

Last edited: