Hello,

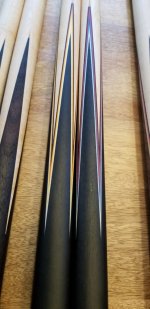

I've always loved Full splice cues. I received 4 Rounceville blanks today, his work is incredible. Look at those return points!

4 Rounceville, a Prather and 2 titlist

I've always loved Full splice cues. I received 4 Rounceville blanks today, his work is incredible. Look at those return points!

4 Rounceville, a Prather and 2 titlist

Attachments

-

20210503_194020 (Medium).jpg119.1 KB · Views: 460

20210503_194020 (Medium).jpg119.1 KB · Views: 460 -

20210503_194035 (Medium).jpg123.9 KB · Views: 459

20210503_194035 (Medium).jpg123.9 KB · Views: 459 -

20210503_194045 (Medium).jpg115.4 KB · Views: 417

20210503_194045 (Medium).jpg115.4 KB · Views: 417 -

20210503_194056 (Medium).jpg144.4 KB · Views: 424

20210503_194056 (Medium).jpg144.4 KB · Views: 424 -

177842872_863528474376643_8627995748500711393_n.jpg199.1 KB · Views: 355

177842872_863528474376643_8627995748500711393_n.jpg199.1 KB · Views: 355 -

179538193_2505870286376590_3628753554210555736_n.jpg85.6 KB · Views: 329

179538193_2505870286376590_3628753554210555736_n.jpg85.6 KB · Views: 329 -

178653056_3754047981373559_2583370386725957036_n.jpg113.4 KB · Views: 376

178653056_3754047981373559_2583370386725957036_n.jpg113.4 KB · Views: 376

Last edited: