I know what you mean, and sometimes I think it is done to hide a flaw, but not always. Some cue makers just like the design and nothing else. But in reference to what you said above I like the bottom of Splice to be as sharp as the end of the points on the top. To me squared points on the bottom of the cue tell me that the cue is not really full spliced, to me it means that the points are inlayed not spliced.

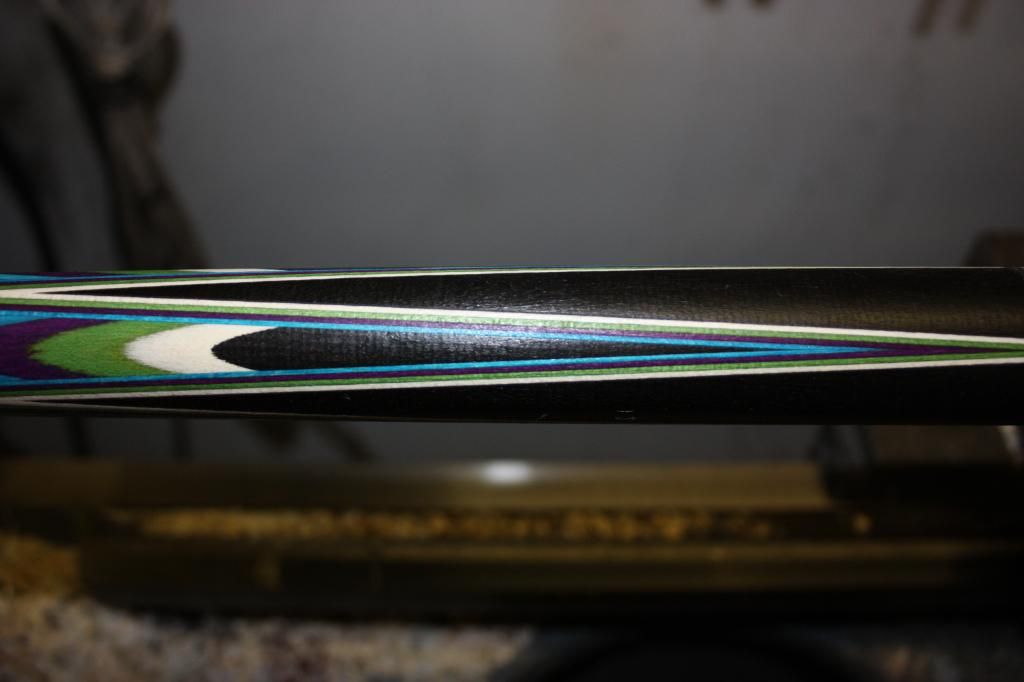

Here is an example of what I am talking about:

This is total BS so you are saying all the Brunswick Titlist cues are not full splice.

It's funny that the only cue makers who comment on how it should be done have never built a full splice blank and turned it into a completed cue all by them self.

Wow I must have struck a nerve dude, the Brunswick 26 1/2 model, Brunswick Carom king, the Brunswick Titlist, and even the Brunswick house cues all come to a sharp point at the bottom of the splice not a square.

I am currently in the process of building a full splice blank with sharp points up and down. No I have not perfected my splice yet because I still need to buy a good band saw and make my fences, however what I said is not BS. You may want to read my comments again because there is no need to be disrespectful, my comments were not disrespectful to anyone.

So please shake off the hang over or what ever other problem you may be having today!!!!!:wink:

Have a great day