Good Point Chris !

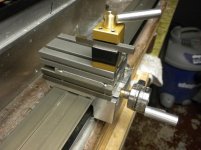

I tried to imply that it only works perfect for one diameter. But I maybe was a bit vague. But, I got past that problem by doing a compound cut on my jaws. I cut it for the shaft size first, then made a second bore for the 1 3/8 bushing size! The larger bore is just enough to true up the outer corners of the jaws, these will grip the bushings true without any fear of damage to the cue since they only grip the bushing. So one gets a "two fer" out of the jaws! And I have a full set of aluminum jaws completely bored to 35mm a full 1.5 inches deep for my metal lathe, That is my accurate chuck!

And I just want to say again: Chris you make a heck of a lathe, the benchmark for others to try to match. I could never ever appreciate that lathe until I actually got one for myself. I had three metal lathes in my shop before I got a CueSmith. Those metal lathes are accurate as one can ask, but for versatility to do cue making tasks, right out of the box, yours is dah bomb ! Thank you.

I tried to imply that it only works perfect for one diameter. But I maybe was a bit vague. But, I got past that problem by doing a compound cut on my jaws. I cut it for the shaft size first, then made a second bore for the 1 3/8 bushing size! The larger bore is just enough to true up the outer corners of the jaws, these will grip the bushings true without any fear of damage to the cue since they only grip the bushing. So one gets a "two fer" out of the jaws! And I have a full set of aluminum jaws completely bored to 35mm a full 1.5 inches deep for my metal lathe, That is my accurate chuck!

And I just want to say again: Chris you make a heck of a lathe, the benchmark for others to try to match. I could never ever appreciate that lathe until I actually got one for myself. I had three metal lathes in my shop before I got a CueSmith. Those metal lathes are accurate as one can ask, but for versatility to do cue making tasks, right out of the box, yours is dah bomb ! Thank you.