I believe yesyua is on his way or maybe already there.I searched the forum, but mostly what I find is something to the effect, "There are no good mechanics in Texas."

I have a 9' Diamond Paragon delivered September 2020. I need some adjustments.

Now that I am finally taming my stoke and actually stoking rather than "hitting" the cue ball, and now that I have many more shots at pocket speed, I see roll-off on at least two corners. In my mind, there is a "soft thud" rather than a rebound sound off a couple cushions near a couple corners. (Actually, the ones that seem to roll off.)

Now, Mike and a helper delivered and set up the table directly from the Diamond factory, and my understanding is Mike is a top level mechanic, perhaps trained by RKC himself. It's also notable that we had a really dry summer, and I never put out the soaker hoses for the foundation. So, that's a variable in any roll off.

When the rails were installed, they used power drills, but when I questioned that, they said that Diamond puts torque limiters on the drills. So, if true, that would address RKC's point about properly adjusting the rail bolts.

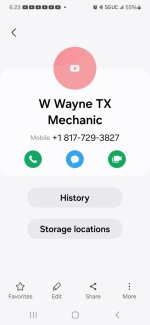

Anyway, I need the table re-leveled (it was perfect for nearly 3 years) and perhaps a check on the torque on the rail bolts. If RKC will be traveling in the area anytime in the next 6 months, I'd wait for him and write a blank check. Otherwise, I'd appreciate any thoughts on top-level mechanics. I've reached out to Richard Black, so maybe I'll get a name there.

Thanks for reading!

He's the only mechanic I let touch my table.

The carom rooms bring him in from NJ.