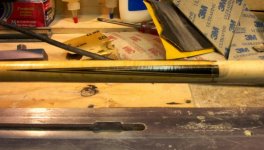

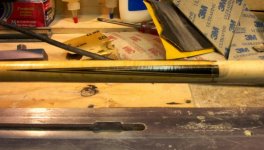

Hello, I am in the process of doing a refinish on an older cue. I have never seen this type of splice points before, what type is it, or are these inlay-ed points that have finished tips?

The interesting thing is that the Birdseye Maple in the forearm extends to the under wrap. Another thing about this cue that seems like a waste, is that the Birdseye in the under wrap is pretty nice quality. Please let me know what you think, I will list some photo's below.

Thanks for any information you can give me in advance!!!!!

Have a great night

The interesting thing is that the Birdseye Maple in the forearm extends to the under wrap. Another thing about this cue that seems like a waste, is that the Birdseye in the under wrap is pretty nice quality. Please let me know what you think, I will list some photo's below.

Thanks for any information you can give me in advance!!!!!

Have a great night