What if we designed a cue-robot like machine...

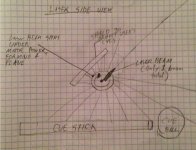

1. That had a fixed pivot point length from the CB of lets say 10" (common bridge point)

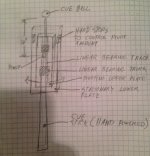

2. Had a linear bearing that the cue rode on in during its entire travel (ensuring a perfectly straight stroke)

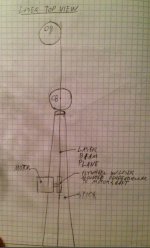

3. It was two plates. A base plate that is stationary relative to the slate, and the top plate, that would pivot with respect to the stationary plate. All of the cue carrying components, such as at the linear bearing, would be attached to the top plate, and move with the top plate.

4. The bottom plate would have hard stops, to limit how many degrees the top plate (and thus the cue) could pivot. The hard stops could be calibrated for exactly 1/2 tip of rotation (for the mounted cue).

5. The cue could be hand powered, and the linear bearing would guide it.

To use it, one would start with the top plate against one of the pivot hard stops. Then, they'd eyeball the alignment of the stick with the CTE points on the CB/OB. They would do this alignment by moving the entire lower plate assembly. They would follow the CTE instruction for the given shot, as to what to align with what.

Once the alignment was set, the user would pivot the top plate until it hits the hard pivot stop in the other direction, which would again be 1/2 tip. (or full tip, whatever the CTE instruction is for the test shot).

Then the user would stroke the cue.

This could be tried for small variations in shot angle, that were still within the same instruction set of CTE. (It would be harder to make the jig fully adjustable to allow all shot ranges). Thus, it could be designed to only follow the instruction set for the 15 deg perception shots, for example.

What do you think? Could this prove or disprove if CTE is a system that follows an explicit set of instructions?

Last edited: