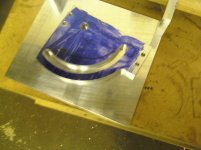

Here is the latest tooling in my full-service shop. I will post more pictures if you like, but this will get you the idea. The fixture is 6" high and 61" long made out of reinforced channel. I machined it to slide in the T-slot of the 10x54 Milling machine since it only has 32" of travel with the dro's installed. The fixture accepts all styles of rails including T rails for antiques, all rails bolt to the fixture in the same manner as the installation on the slate. The same stresses are on the rail so a warped rail can be cut perfectly. There is some alignment on GC style rails with the floating nut plate design, but you have 2 accurate faces to measure off for parallel. Let me know what you think!

Rob

PS; this is far more accurate than how the factory does it.. though it takes about 1.5 hours to do a set

Rob

PS; this is far more accurate than how the factory does it.. though it takes about 1.5 hours to do a set