I don't work at or for Diamond, and I'm not a dealer, I'm a billiards technician, independent contractor if you want to title me. If loosing a customer means not pricing the product low enough so the customer can afford it means picking up a new customer, I look at it as begging for sales, and screwing the customer that DID pay the going price! I agree, not everyone can afford a Diamond ball polisher, nor a Diamond pool table, but I guess that's the difference between who gets them, and who don't. But when people complain about the price of something as in their mind being to high, but would spend ridiculous amounts of money on other things, to me...that makes them hypocrites!Zims Rack said:I've seen the Diamond Ball Polisher (commercial) in use and the balls before and after polishing... it DOES work great! To me, it's only worth the money if you're going to be polishing 10+ racks of balls on a weekly or even monthly basis. I don't know many that would spend $400, let alone $800 on a ball polisher for 1 set of balls for their home use.

Personally, I run Zim's Rack 8-Ball League, which is not held at pool rooms, but at bars, taverns, bowling alleys, etc, with no more than 2 tables. Most of them only have 1 table. I would like to have a ball polisher that is portable (1 person w/out a dolley) that I could take to each bar once a month and polish the balls. The players will notice a difference, most likely not the bar owner/manager. The players will talk about the "new" balls, and say something to the owner/manager. Who knows, word gets out I might have people or bars that participate in my league buying/making their own affordable ball polisher.

Realkingcobra- I don't remember if you work at Diamond or are an authorized dealer, but either way... you shouldn't be proud of burning bridges. You should treat everyone as if they were in the market for Diamond Products and could afford them. You never know who or how many customers you could lose by burning one bridge. A bridge is a pathway to everywhere!

Zim

The headline should read "Save money, build your own ball polisher, it don't work as good as the best, but does shine the balls somewhat" instead of "Build your own ball polisher at home, it's just as good as all the others, because all balll polishers are the same"

If I could have designed the Diamond ball polisher cheapier I would have, but not at the expence of it wearing out or breaking down over time, to me that was very important, so I designed the ball polisher to last for as long as possible!

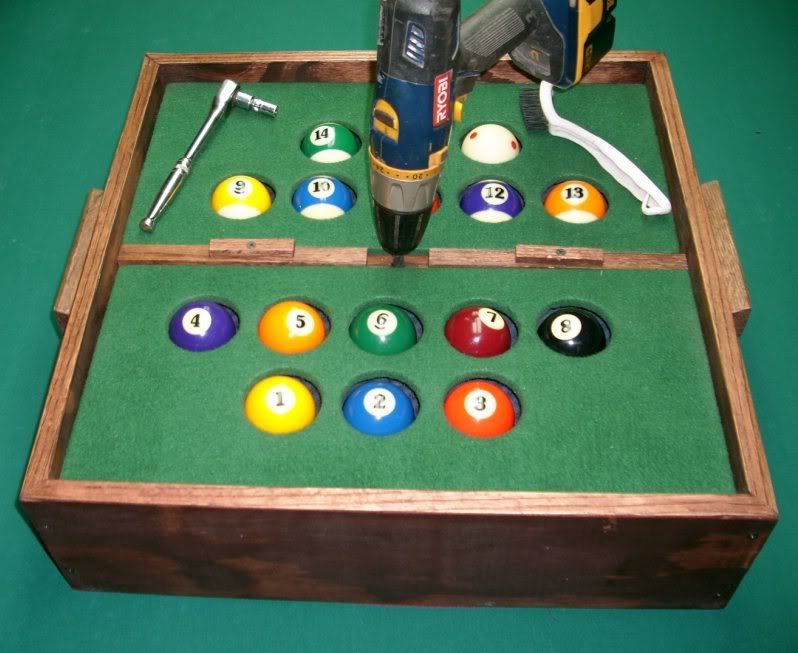

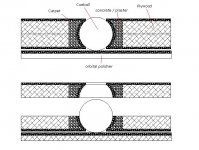

I designed it to give you an area to clean the balls, and another area to shine the balls, reason being..you can't keep shining the balls where you clean them, over time, that don't work.

I designed the ball polisher to rotate the balls while spining them, and the sprokets to keep the balls from crashing into each other as to eliminate the marks on the balls in the finished shine.

I designed it to be quiet when in operation. I slowed down the motor so it wouldn't spin the balls to fast as to build up heat in them, or over heat the drive motor.

I don't burn bridges, I built bridges!!!!!! Like it or not!!!! What have YOU done, or ANY of you done lately?

Glen, the "Realkingcobra"