I just received my cue back from the maker after a refinish and had a new shaft made. I have had the cue back in my hands for literally 9 days.

Well went to play tonight and when I went to snug the shaft up... It went past snug... Not like i was cranking the crap out of it, just snugging it up.

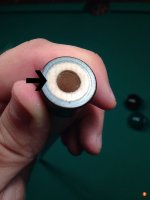

Cue has g10 3/8 10 in it, and the threads just disintrigrated... What the hell happened?

Never had a shaft do this or even seen one do this. Been playing with 3/8 10 pins for over a decade!!!

Tried to call maker, but they are closed til tomorrow. My assumption is they will fix it, but I would like to know the possible causes

Just a bad shaft? Improper machining? I dont get it!!!

Sent from my iPhone using Tapatalk

Well went to play tonight and when I went to snug the shaft up... It went past snug... Not like i was cranking the crap out of it, just snugging it up.

Cue has g10 3/8 10 in it, and the threads just disintrigrated... What the hell happened?

Never had a shaft do this or even seen one do this. Been playing with 3/8 10 pins for over a decade!!!

Tried to call maker, but they are closed til tomorrow. My assumption is they will fix it, but I would like to know the possible causes

Just a bad shaft? Improper machining? I dont get it!!!

Sent from my iPhone using Tapatalk